Bag of pigment powder tipping onto discharge conveyor after filling

This semi-automatic system fills batch inclusion bags with blended pigment powders used for road markings. After filling, the bags are conveyed to a palletizing station.

Process Description

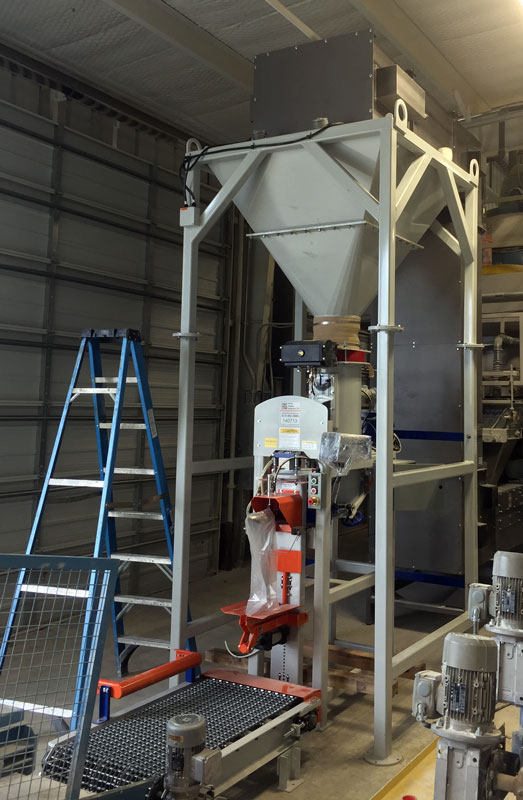

Blended pigment powder used for road marking is conveyed to a bucket elevator that discharges it into a 25 cubic foot hopper. Then, the powder flows by gravity into the air chamber of the valve bag air packer.

An operator places an inclusion type valve bag onto the spout of the filling machine and presses the start button. This activates the filling cycle, and the machine pressurizes the air chamber pushing the pigment powder into the bag. Once the valve bag has reached a set target weight of 50 lbs., a pneumatic bag chair tips and drops the bag onto a wire mesh discharge conveyor.

The bags are conveyed through an inclined bag flattening conveyor up to a manual palletizing station where operators pick up the bag and stack them on a pallet loading station.

Front view of system for filling 50 lb. batch inclusion bags with pigment powder

Side view of bucket elevator and system for filling 50 lb. batch inclusion bags with pigment powder

Valve bag filling machine air packer used to fill 50 lb. inclusion bags with roadway pigment powder