« Equipment and Systems

-

- Open Mouth Baggers

- Valve Bag Filling Machines

- Bulk Bag Filling Machines

- Bulk Bag Unloaders

- Bag Sewing Machines

- Bag Sealing Equipment

- Bag Handling Conveyors

- Manual Palletizing Systems

- Robotic Bag Palletizers

- Gantry Palletizer Systems

- Automated Pallet Wrappers

- Automatic Bagging

Machines & Systems - IBC Blending

- Stainless Steel Intermediate Bulk Containers

Small Feeders

Swiss precision. Customized solutions. Competitive prices!

These small feeders use a vibrating, closed loop, resonant frequency to feed or dose foods, plastics, chemicals, and ceramics. They are recognized as the vibratory feeder of choice for many applications such as pelletized and friable materials that are not easily fed by screw or belt feeders. Add food seasoning equipment and coating machines that use electrostatics to improve product consistency with 100% control of powder usage. Choose from a complete line of small feeders including vibratory tray feeders, flexible wall feeders, single and twin screw feeders, belt loss-in-weight feeders, chemical feeders, additive feeders, dosing feeders, liquid feeders, weigh belt feeders and volumetric and gravimetric control systems.

Try before you buy! Testing and trial models are available for lease.

Contact us today to set up a test to see how these feeders can reduce your production costs and increase product consistency.

Available Models

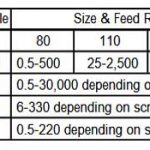

Volumetric Dry Feeders

These patented volumetric feeders, or tray feeders, are ideal for many applications to replace traditional single or twin screw feeders. The feeder drives find the resonant frequency of the tray and material to provide accurate feed rates and a turn-down ratio of over 1:100. Feeder models include medium sized, universal vibratory tray feeder, as well as special feeders for powders where the hopper vibrates in tune with the tray.

- Excellent accuracy with gentle motion that will not degrade your product or add extra heat

- Adjustable feed rates with different models offering feed rates ranging from 0.5 – 12,000 pounds per hour

- Maintenance free and very easy to clean with no moving parts

- No maintenance-intensive parts and components such as motors, gears, screws, bearings, etc.

- Resonant vibration system moves the working frequency of the tray to the resonant frequency, between 35-75 Hz

- Specially developed amplitude sensor measures the amplitude of the vibration and feeds it back to the SCR

Images

Click a thumbnail below for a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

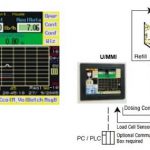

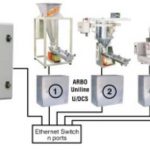

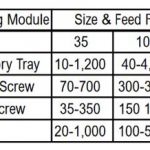

Gravimetric Feeders

Gravimetric feeders, or loss-in-weight tray feeders, are usually mounted hanging from a mezzanine, with excellent access all around. Static weigh frames with 3 load cells are available for all sizes.

- Totally integrated construction of static weigh frame with the feeder mechanism and the LIW controller

- Touch screen feeder control system is a part of the feeder and can be used to connect up to 5 other units

- All materials are electropolished 304 or 316 stainless steel

Images

Click a thumbnail below for a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480