« Equipment and Systems

-

- Small Bag Filling Machines

- Open Mouth Bagging Machines

- Valve Bag Filling Machines

- Automatic Bag Placers

- Bulk Bag Filling

- Bulk Bag Unloaders

- Bag Sewing Machines

- Bag Sealing Equipment

- Bag Handling Conveyors

- Manual Palletizing Systems

- Robotic Bag Palletizers

- Gantry Palletizer Systems

- Automated Pallet Wrappers

- Automatic Bagging

Machines & Systems - IBC Blending

- Stainless Steel Intermediate Bulk Containers

Open Mouth Bagging Machine

Use an open mouth bagging machine to weigh and fill open top style bags with granules, pellets, powders, flakes, and fibrous materials.

An open mouth bagging machine has a larger spout to fill open top style bags, sacks, boxes, totes, and more. These machines typically fill bags to weights of 20-110 pounds (9-50 kilograms) using mechanical or digital bagging scales at rates up to 24+ bags per minute (1,440+ bags per hour). They are used in different types of industries including animal feed, seed, pet food, fertilizer, salt, landscaping products, chemicals, food ingredients, nuts, and more.

What is the difference between a gross weigh bagging machine and a net weigh bagging machine?

A gross weigh bagging machine weighs the material in the bag as it is being filled. A net weigh bagging machine pre-weighs the material in an internal weigh hopper and then dumps it into the bag. Filling bags using a net weigh bagging machine is about 2 times faster because the operator can position and fill a bag clamped to the spout as the internal weigh hopper is being filled above.

Click a link below to jump to a section on this page:

- Model 190 - All Mechanical Open Mouth Bagging Machine (4 Bags/Min)

- Model 200 - Digital Open Mouth Bagging Machine (4-5 Bags/Min)

- Model 350 - DigitalPLUS Open Mouth Bagging Machine (6-10 Bags/Min)

- Models 600-1500 - Digital High-Speed Net Weigh Bagging Machine (8-24+ Bags/Min)

- Belt Fed Bagging Machine

- Auger Fed Bagging Machine

- Vibratory Fed Bagging Machine

Call: (979) 217-1480

Need to fill small bags and pouches weighing 1-25 pounds? A small bag filling machine typically fills bags and pouches to weights of 1-25 pounds using a digital net weigh bagging scales at rates up to 30+ bags and pouches per minute or (1,800 per hour). View Small Bag Filling Machines

Available Models

Model 190

All Mechanical Open Mouth Bagging Machine

No electricity or compressed air is required for basic operation. This is an ideal entry-level bagging machine for start up operations!

The base model all mechanical open mouth bagging machine is designed for packaging granular and free-flowing products into open mouth bags (50 lb grain bags being the most popular). An empty bag is placed on the fill spout and secured using cam lock bag grips. The operator pulls down on a mechanical lever and product flows freely by gravity from a supply hopper with a scale support, through a gravity gate into a funnel spout, and into the bag.

Fill rate: 4 bags per minute (at 50 lbs each) or approximately 190 bags per hour

Accuracy: +/- 4 ounce (100 gram) accuracy

Bag weight range: 10-110 pound bags (5-50 kg)

Bag types: paper, plastic, and poly-woven open mouth bags

- Deer Corn

- Whole Corn

- Cracked Corn

- High Moisture Corn

- Grains

- Seeds

- Nuts

- Flour

- Rice

- Soybeans

- Animal Feed

- Bird Seed

- Sugar

- Salt

- Fertilizer

- Ice Melting Salt

- PVC Resin

- Plastic Pellets

- Wood Pellets

- Activated Carbon

- Pea Gravel

- Dry Sand

- Aggregate

(3/4" down to coarse sand)

Included: mild 10-gauge steel construction, fully mechanical cam grip bag spout, gravity gate with two position open / close gate, calibration weight set (lb or kg)

Materials of Construction Options: mild 10-gauge steel (standard), stainless steel product contact surfaces, all stainless steel, all stainless steel for food grade applications

Spout Sizes: 22 inch oval, 29 inch oval, 21 inch football, 25 inch football, 31 inch football, special sizes made to order

Optional Upgrades: stainless steel construction, center grip spout with foot pedal bag clamp activation, dust tight spout with foot pedal bag clamp activation, belt feeder for semi-free flowing / sticky products, auger feeder for powders and finely ground products, box / pail filling attachment, mechanical bag counter

Compressed Air: none required

Electrical: none required

Learn more about a complete open mouth bagging system using this machine.

Images

Click or tap a thumbnail below to view a larger image.

Videos

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Model 200

Digital Open Mouth Bagging Machine

This is an upgraded version of the Model 190 with a digital scale that has 100 kg load cells. Save multiple bag filling recipes. Start the filling process on this bagging machine with the press of a button!

The base Model 200 is designed for packaging granular and free-flowing products into open mouth bags (50 lb grain bags being the most popular). An empty bag is placed on the fill spout and secured using cam lock bag grips. The bag filling process is started by pushing the start button to open the internal flow control gate. Product flows freely by gravity from a supply hopper with a scale support, through a gravity gate into a funnel spout, and into the bag.

This type of open mouth bagging machine uses an automatic digital gross weigh scale to simultaneously fill and weigh the product directly in the bag. Add a belt feeder or auger feeder for more difficult flowing products or powders.

Fill rate: 4-5 bags per minute (at 50 lbs each) or approximately 200 bags per hour

Accuracy: +/- 4 ounce (100 gram) accuracy

Bag weight range: 10-110 pound bags (5-50 kg)

Bag types: paper, plastic, and poly-woven open mouth bags

- Deer Corn

- Whole Corn

- Cracked Corn

- High Moisture Corn

- Grains

- Seeds

- Nuts

- Flour

- Rice

- Soybeans

- Animal Feed

- Bird Seed

- Sugar

- Salt

- Fertilizer

- Ice Melting Salt

- PVC Resin

- Plastic Pellets

- Wood Pellets

- Activated Carbon

- Pea Gravel

- Dry Sand

- Aggregate

(3/4" down to coarse sand)

Included: mild 10-gauge steel construction, fully mechanical cam grip bag spout, digitally controlled gravity gate with two position open / close gate, digital scale with two 100 kg load cells, IP69K stainless steel digital controller, tool-less mechanical flow rate adjustment gravity gate feeder, calibration weight set (lb or kg)

Materials of Construction Options: mild 10-gauge steel (standard), stainless steel product contact surfaces, all stainless steel, all stainless steel for food grade applications

Spout Sizes: 22 inch oval, 29 inch oval, special sizes made to order

Optional Upgrades: stainless steel construction, center grip spout with foot pedal bag clamp activation, dust tight spout with foot pedal bag clamp activation, belt feeder for semi-free flowing / sticky products, auger feeder for powders and finely ground products, box / pail filling attachment

Compressed Air: 80 PSI required at 1 CFM per bag fill cycle

Electrical: 110 or 220 volt / 1 phase / 60 cycle

Learn more about a complete open mouth bagging system using this machine.

Images

Click or tap a thumbnail below to view a larger image.

Watch a Demonstration Video:

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Model 350

DigitalPLUS Open Mouth Bagging Machine

This is a very popular digital bagging machine used to fill up to 10 bags per minute, or about 500 bags per hour. It includes a more advanced scale controller with foot pedal or wand switch activation.

The base Model 350 is designed for packaging granular and free-flowing products into open mouth bags (50 lb grain bags being the most popular). An empty bag is placed on the fill spout, and the operator depresses the foot pedal to clamp the bag to the spout. Product automatically starts flowing by gravity into the bagging scale and then into the bag. Once the bag has reached a set target weight, the internal flow control gate closes, and the bag clamp releases the bag from the fill spout automatically dropping it onto a bag closing conveyor below.

This type of open mouth bagging machine uses an automatic digital gross weigh scale to simultaneously fill and weigh the product directly in the bag. Add a belt feeder, twin auger feeder, or vibratory feeder for more difficult flowing / sticky products or powders.

Fill rate: 6-10 bags per minute

Accuracy: 0.1 lb (0.05 kg) weight accuracy

Bag weight range: 10-110 pound bags (5-50 kilograms)

Bag types: paper, plastic, and poly-woven open mouth bags

- Deer Corn

- Whole Corn

- Cracked Corn

- High Moisture Corn

- Grains

- Seeds

- Flour

- Rice

- Soybeans

- Barley

- Animal Feed

- Bird Seed

- Sugar

- Salt

- Fertilizer

- Ice Melting Salt

- PVC Resin

- Plastic Pellets

- Wood Pellets

- Activated Carbon

- Pea Gravel

- Dry Sand

- Aggregate

(3/4" down to coarse sand)

Included: mild 10-gauge steel construction, gravity gate feeder with two speed bulk and dribble fill cycle, mechanical flow adjuster, low voltage valves and controls with power supply, dust-tight or center grip spout with foot pedal activation, stainless steel controller (weights and measures approved) with 99 memory retained fill recipes

Materials of Construction Options: mild 10-gauge steel (standard), stainless steel product contact surfaces, all stainless steel, all stainless steel for food grade applications

Spout Sizes: 21 inch football design, 25 inch football design, 31 inch football design, special sizes made to order

Optional Upgrades: stainless steel construction, gravity gate AND vibratory feeder for maximum accuracies, belt feeder for semi-free flowing / sticky products, auger feeder for powders and finely ground products, box / pail filling attachment. We also offer a less expensive version of this bagging machine that uses a simplified digital scale controller.

Compressed air: 80 PSI required at 1 CFM per bag fill cycle

Electrical: 110 or 220 volt / 1 phase / 60 cycle, 440 volt / 3 phase / 60 cycle

Learn more about a complete open mouth bagging system using this machine.

Images

Click or tap a thumbnail below to view a larger image.

Videos

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

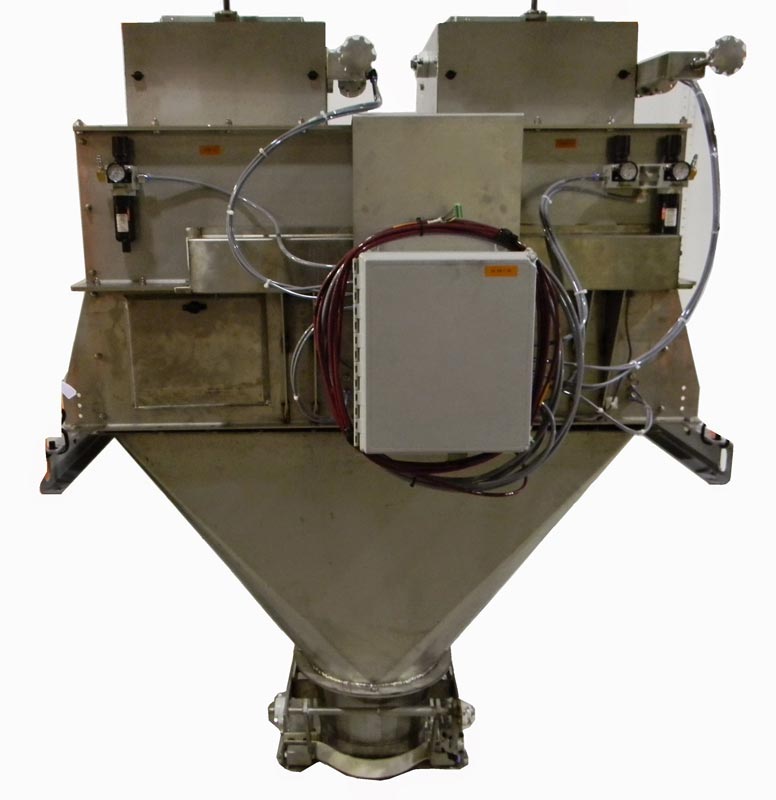

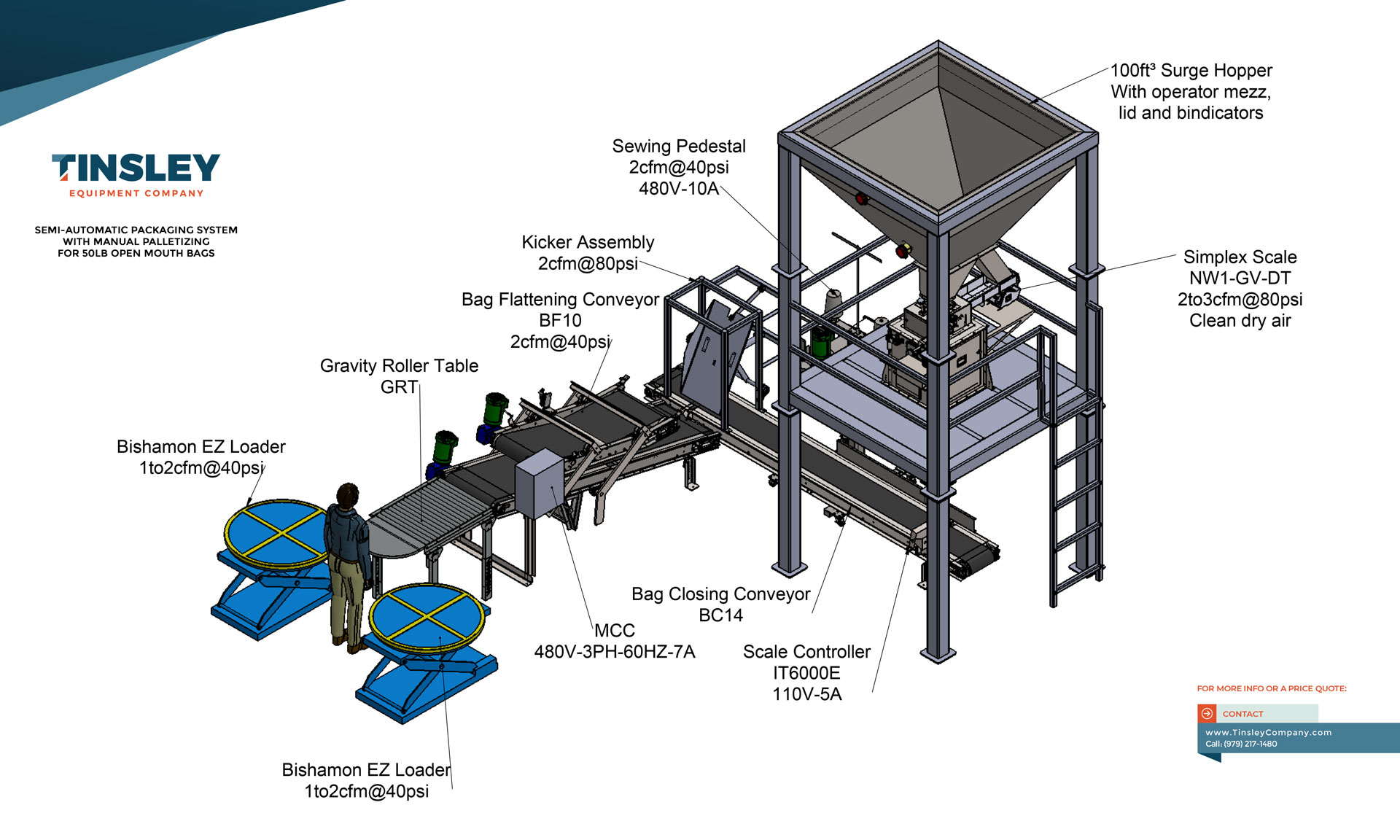

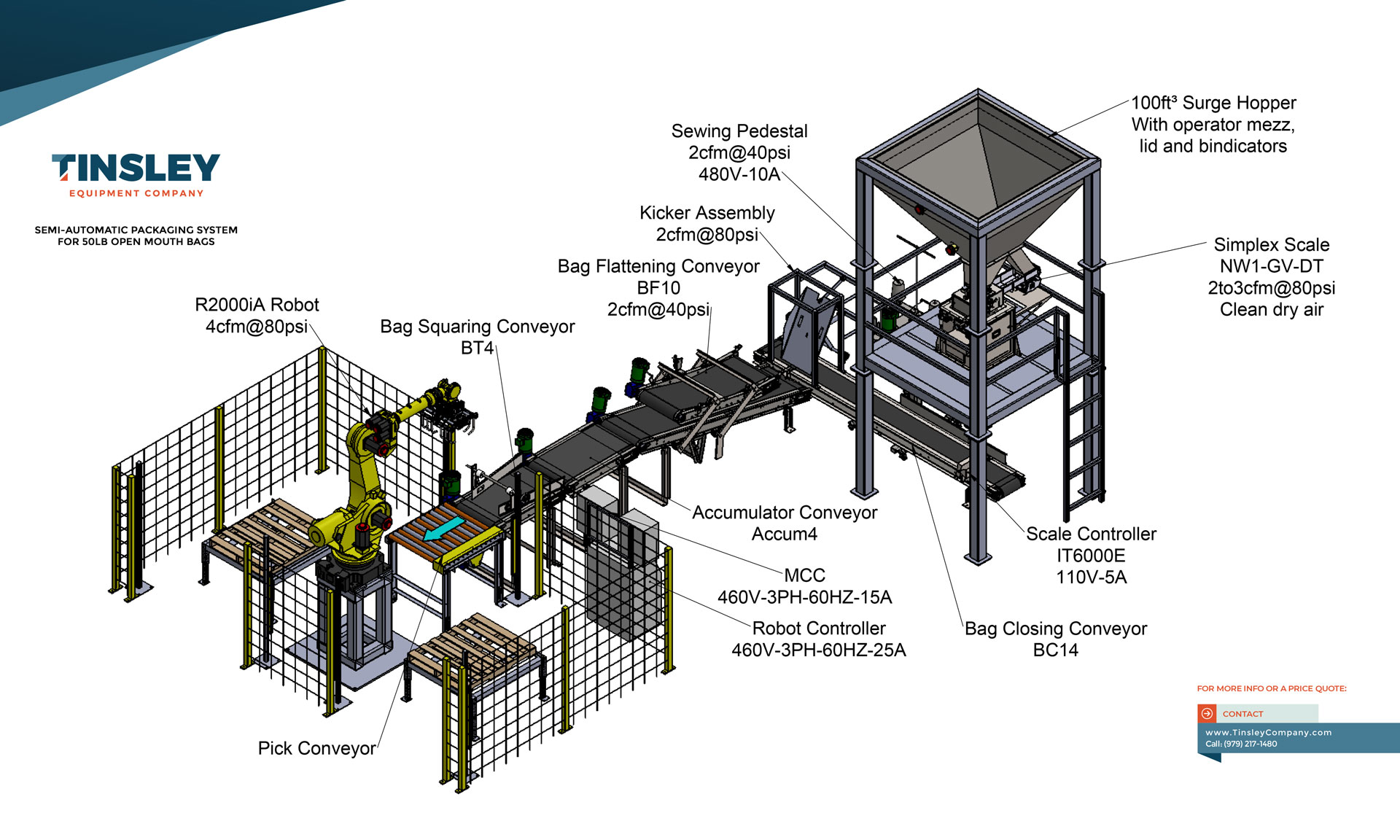

Models 600 - 1500

Digital High-Speed Net Weigh Bagging Machine

This type of open mouth bagging machine fills the fastest with speeds up to 24 bags per minute or more. It is considered the open mouth bagging machine of choice for high volume or industrial bagging operations that bag animal feed, minerals, salt, aggregate, corn, nuts, and more.

The base Model 600 is designed for packaging granular and free-flowing products into open mouth bags (50 lb grain bags being the most popular). An empty bag is placed on the fill spout, and the operator depresses the foot pedal to clamp the bag to the spout. The fill cycle starts, and the product is discharged from the internal weigh hopper, through a funnel spout, and into the bag. At the same time as material is discharged, the machine loads product into the internal weigh hopper for the next fill cycle. This type of machine is an automatic net weigh bagging machine that pre-weighs material before discharging into a bag or container. Add a belt feeder or a twin auger feeder for more difficult flowing products or powders. Add a vibrating pan feeder for more precise dosing.

Fill rates (accuracies of ± 2 ounces for most products):

- Model 600 (single scale / simplex) 14 bags per minute

- Model 1100 (double scale / duplex) 22 bags per minute

- Model 1500 (triple scale / triplex) Up to 24+ bags per minute

Bag weight range: 10-110 pound bags (5-50 kilograms)

Bag types: paper, plastic, and poly-woven open mouth bags

Need automation? Add an automatic bag placer or robotic bag palletizer!

- Deer Corn

- Grains

- Seeds

- Almonds

- Flour

- Rice

- Soybeans

- Barley

- Animal Feed

and Cubes - Molasses Feed

- Bird Seed

- Fish Feed

- Sugar

- Salt

- Cake Mixes

- Spices

- Nuts

- Milk Powder

- Fertilizer

- Ice Melting Salt

- PVC Resin

- Plastic Pellets

- Dry and Damp Sand

- Aggregate (3/4" down to coarse sand - Add belt or vibratory feeder for larger aggregate)

Feeder types: gravity gate feeder, gravity gate and vibrating pan feeder (for maximum accuracy), belt feeder, twin auger feeder, and heavy duty aggregate vibrating pan feeder

Materials of Construction Options: mild 10-gauge steel (standard), stainless steel product contact surfaces, all stainless steel, all stainless steel for food grade applications

Various Spout Sizes Available with These Types:

- Straight spout - without bag clamp, includes foot pedal for discharge.

- Center grip spout - air-operated for use with non-dusty products. Includes foot pedal clamp activation, solenoid / air cylinder bag clamp assembly.

- Dust tight spout - air-operated for use with dusty products. Includes foot pedal clamp activation, solenoid / air cylinder bag clamp assembly.

- Clam shell spout - with foot pedal bag clamp activation

- Balloon spout – air-operated with inflatable bladder for use with extremely dusty products. Includes hand valve activation with flow regulator.

Internal Weigh Hopper: 2.0 cubic foot or 3.5 cubic foot capacity, tool-less access doors for easy cleanout / maintenance, digital weigh controller with programmable memory retained recipe codes (W&M approved)

Optional Upgrades: Multi dump feature to fill bulk bags / super sacks, LabView data collection application, industrial duty uninterruptible power supply, components to interface with an automatic bag placer, rolling product stop gate for vibrating pan feeder, heavy duty vibrating pan feeder, various belt feeder types with variable speed drive, all stainless steel / food grade twin auger feeders, dust pick up system, air-tight stainless steel blade Salina Vortex Slide Gate

Compressed Air: 80 PSI required at 1 CFM per bag fill cycle

Electrical: 220 volt, 380 volt, 440 volt, or 575 volt / 3 phase / 60 cycle

Learn more about a complete open mouth bagging system using this machine.

Images

Click or tap a thumbnail below to view a larger image.

Videos

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

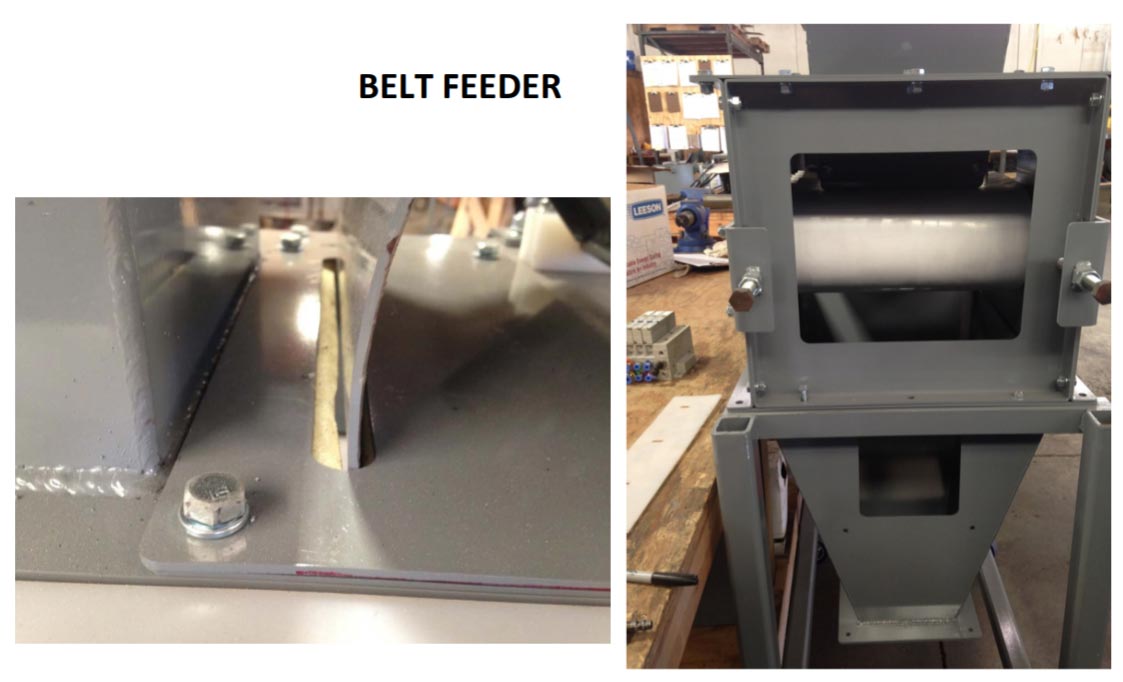

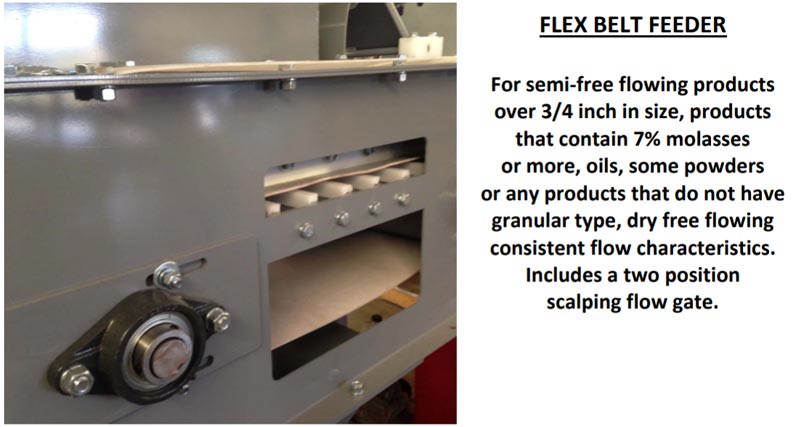

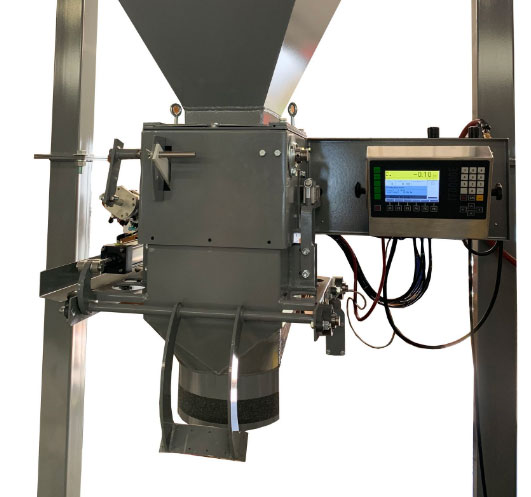

Belt Fed

Open Mouth Bagging Machine

Add a belt feeder to any of the machines above for bagging non-free flowing products like sticky animal feeds, wood chips, screened soils, and some flours like cake mix.

Belt feeders are designed for semi-free flowing products over 1 inch in size, materials containing 7% molasses or more, oils, certain powders, or any product that is not dry, granular, and free flowing. Each unit includes an adjustable stream depth regulator and a belt scraper to ensure consistent, clean operation.

Product flows by gravity from a supply hopper into the inlet of the belt feeder. When a fill cycle starts, the product is conveyed through a specially designed belt feeder that conditions and delivers it in an even and consistent flow to the bagging machine. When the target weight has been reached, the belt feeder stops and the cutoff gate in the machine closes. Then, the bag is released from the scale. For difficult to handle materials, the gravity gate is removed completely.

Fill rate: 1-8 bags per minute

Accuracy: +/- 0.5-1% of target weight

Bag weight range: 20-110 pound bags (9-50 kilograms)

Bag types: paper, plastic, and poly-woven open mouth bags

- Animal Feed

with Sticky Molasses - Cattle Cubes

- Range Cubes

- Hay Cubes

- Fish Feed

- Milk Powder

- Cake Mixes

- Brown Sugar

- Damp Sand

- Gravel

- Soil

Included: Flex belt feeder with two-position scalping flow gate, variable speed drive with digital scale controller interface, mild steel construction

Materials of construction options: mild 10-gauge steel (standard), stainless steel product contact surfaces, all stainless steel, all stainless steel for food grade applications

Additional upgrades: Endless food grade belt, heavy duty aggregate belt, white oil resistant belt (for pet foods, animal feeds, and various products that contain oils)

Compressed air: 80 PSI required at 1 CFM per bag fill cycle

Electrical: 220 volt, 380 volt, 440 volt or 575 volt / 3 phase / 60 cycle

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

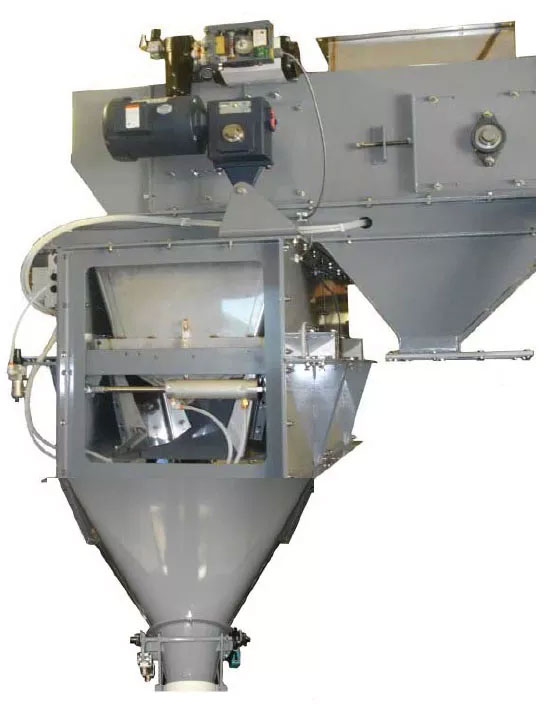

Auger Fed

Open Mouth Bagging Machine

Add an auger feeder to any of the machines above for bagging flour, fine powders, or other finely ground products that will flood past a gravity gate or belt feeder.

Product flows by gravity from a supply hopper into the inlet of the auger feeder. When a fill cycle starts, the product is conveyed through a specially designed auger feeder that conditions and delivers it in an even and consistent flow to the bagging machine. When the target weight has been reached, the auger feeder will stop and the cutoff gate in the machine closes. Then, the bag is released from the scale.

Fill rate: 1-5 bags per minute (at 50 lbs each)

- Note: Production speeds are decreased 25-35% with auger feeders to prevent further aeration of the product.

Accuracy: +/- 0.5-1% of target weight

Bag weight range: 20-110 pound bags (9-50 kilograms)

Bag types: paper, plastic, and poly-woven open mouth bags

- Powders

- Flour

- Cake Mixes

- Spices

- Milk Powder

- Chemical Powders

- Pigments

Included: Progressive pitch, twin 6-inch augers with 2HP AC variable speed controls interfaced with digital scale controller, drop bottom cleanout doors, mild steel construction

Materials of construction options: mild 10-gauge steel (standard), stainless steel product contact surfaces, all stainless steel, all stainless steel for food grade applications

Optional upgrades: Air purge / cinch seal kits in mild or stainless steel, safety door switches for drop bottom doors

Compressed air: 80 PSI required at 1 CFM per bag fill cycle

Electrical: 220 volt, 380 volt, 440 volt or 575 volt / 3 phase / 60 cycle

Dust collection: 400 CFM minimum

Images

Click or tap a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Vibratory Fed

Open Mouth Bagging Machine

Add a vibratory pan feeder to any of the high-speed net weigh bagging machines above to fill bags with free-flowing granular products and pellets into bags with a high degree of accuracy. Vibratory feeders can also be heavy duty for products like aggregate.

Vibratory pan feeders are a must when target fill weight accuracy is critical.

During each filling cycle, product flows by gravity from the supply hopper into a pantleg diverter, which directs material to both a gravity gate and a vibratory pan feeder. The gravity gate delivers fast, bulk flow, while the vibratory feeder provides slower, dribble flow. As the target weight is approached, the gravity gate closes, and the vibratory feeder finishes the fill with precise dribble feeding until the exact weight is reached. Then, the bag is automatically released from the scale.

Fill rate: 1-10 bags per minute (at 50 lbs each)

Accuracy: +/- 0.5-1% of target weight

Bag weight range: 20-110 pound bags (9-50 kilograms)

Bag types: paper, plastic, and poly-woven open mouth bags

- Grains

- Seeds

- Flour

- Rice

- Soybeans

- Animal Feed

- Bird Seed

- Wood Pellets

- Activated Carbon

- Pea Gravel

- Sugar

- Salt

- Cake Mixes

- Spices

- Milk Powder

- Fertilizer

- Ice Melting Salt

- PVC Resin

- Plastic Pellets

- Dry Sand

Included: Pantleg diverter, 8” x 30” electromagnetic vibratory feeder with variable speed controls, SCR and communication package to digital scale controller, 110V-1PH Standard

Materials of construction options: mild 10-gauge steel (standard), stainless steel product contact surfaces, all stainless steel, all stainless steel for food grade applications

Optional upgrades: Heavy duty Eriez vibratory pan feeder, product stop gate at discharge of vibratory pan (recommended for products that roll like walnuts, hazelnuts, prilled products, some lentils and pulses, etc.)

Compressed Air: 80 PSI required at 1 CFM per bag fill cycle

Electrical: 110 volt / 1 phase / 60 cycle

Need help fast? Use our Express Contact Form

Call: (979) 217-1480