Food grade intermediate bulk container loaded onto an IBC discharge station above bag packaging equipment

Food grade intermediate bulk containers, or IBCs, are easier-to-use, clean, and add into existing operations at food and beverage processing and packaging plants.

The simplest version of an IBC discharge system would include a set of IBCs and a discharge station. This would replace traditional bulk bag unloaders and bulk bags.

Food Grade Intermediate Bulk Containers…

- Are stackable and designed for long term storage and transfer by forklift (Bulk bags are not as durable or reusable and don’t stack as well as an IBC.)

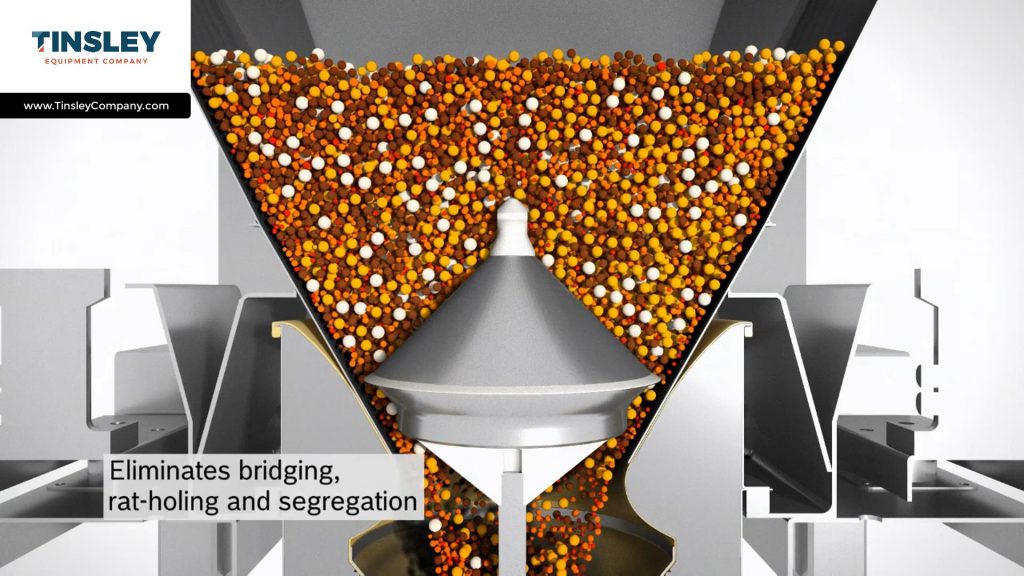

- Include an integrated cone valve that discharges blended powders accurately, while avoiding rat holing, segregation, or bridging (It can be more difficult to accurately discharge product precisely using a bulk bag.)

- Provide dust-tight containment when an IBC is connected to a discharge station (Bulk bags require extra equipment or manual intervention to achieve a dust tight connection.)

- Allow you to blend recipes fast inside of an IBC (You cannot easily tumble and blend seasoning recipes and drink flavorings inside a bulk bag.)

- Are easy-to-clean, with less than 12 components.

IBC Discharge Station

- Automatic dust-tight connection – no manual intervention is required once the food grade IBC is lowered onto the discharge station by forklift

- Meter the discharge of products at a controlled rate or continuous flow using low-pressure air

- Bin vibrators ensure complete discharge of the food grade IBC

- Easy-to-clean with minimal downtime – can be disassembled in minutes

Stainless steel food grade intermediate bulk container being lowered onto a demonstration discharge station

IBC discharge station with dust tight connection raises and lowers cone valve inside IBC to dispense seasonings, drink mixes, and more to equipment below

Benefits of a Food Grade Intermediate Bulk Container System

IBC container being raised by forklift

- Easy-to-use – transfer, store, and discharge raw materials, seasonings, and finished snack food products

- Easy-to-clean – designed for use with food-grade products with minimal downtime for cleaning

- Easy-to-expand system – fit into many existing operations within your processing plant

Blended drink mix being loaded into stainless steel IBC

Example – Filling an IBC with a 50 pound bag dump station

- Load and fill IBC with seasonings, drink mixes, flavorings, nuts, seeds, or other food products using a bag or box dump station

- Cyclonic fill head ensures maximum dust containment

- Optional floor sensors automatically lower the fill head onto the IBC when it is in position

- Optional floor scale can be included to precisely fill IBC to set target weight

Example – Feeding seasoning systems or packaging equipment

- Lower the IBC onto a discharge station using a forklift

- Supply raw nuts and seeds to electrostatic seasoning system

- Collect seasoned products in an IBC for temporary storage

- Transfer seasoned products to packaging equipment

Volumetric feeder doses raw cashews into enrobing drum for seasoning

Watch a Video

Learn more about Stainless Steel Intermediate Bulk Containers