« Equipment and Systems

-

- Small Bag Filling Machines

- Open Mouth Bagging Machines

- Valve Bag Filling Machines

- Automatic Bag Placers

- Bulk Bag Filling

- Bulk Bag Unloaders

- Bag Sewing Machines

- Bag Sealing Equipment

- Bag Handling Conveyors

- Manual Palletizing Systems

- Robotic Bag Palletizers

- Gantry Palletizer Systems

- Automated Pallet Wrappers

- Automatic Bagging

Machines & Systems - IBC Blending

- Stainless Steel Intermediate Bulk Containers

Small Bag Filling Machine

Fill 600-1,500 small bags, stand up pouches, or containers per hour.

Use a small bag filling machine to weigh and fill bags and stand up pouches with many different types of free-flowing, dry bulk goods. This includes but is not limited to food products such as coffee beans, nuts, seeds, candy, pasta, granola, hop pellets, pet food, feed pellets, rice, and more. They can also be used to fill boxes and rigid containers.

These types of filling machines can be semi-automatic or fully automatic. They greatly increase bag filling speeds compared to hand scooping, filling, and manually weighing bags. All weigh fill machines include a digital scale controller that allows for easy set up and adjustments on the fly for filling with many different types of products.

Experience trouble-free weigh filling for many years with these machines available from industry leaders!

Click a link below to jump to a section on this page:

- Model SM900 Small Bag Filling Machine (8-15 / Min)

- Models S600-S1500 Small Bag Filling Machines (Up to 30+ / Min)

Call: (979) 217-1480

Need to fill larger bags weighing 20-110 pounds? View the Open Mouth Bagging Machine or Valve Bag Filling Machine pages.

Available Models

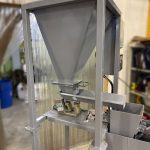

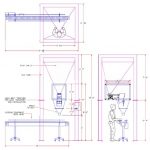

Model SM900 - Small Bag Filling Machine (8-15 Bags, Stand Up Pouches, or Containers / Min)

This is a high quality, industrial strength filling machine with a single or double scale and foot pedal activation. It is available as a tabletop version or with a standing leg kit.

Electrical only. No compressed air required.

Note: This is not an entry-level filling machine. It is designed for years of heavy use, wash downs, etc.

Stop hand scooping and start weigh filling! First, product is placed in the supply hopper. Next, a vibratory feeder moves the product from the supply hopper to the weigh hopper, where a bag, pouch, or container full of product is automatically weighed. When a set target weight has been reached, the controller stops the feeder, and the weigh hopper automatically opens and dumps the product into a bag, stand up pouch, or container located below. Then, they are sent through bag sealing equipment.

For faster filling speeds (up to 900 fills per hour) and mixing of products, we recommend adding a second scale and vibratory feeder.

- Coffee beans

- Almonds

- Small aquarium

rocks and dry sand - Beans (pinto, lima, etc.)

- Capsules

- Cereal (round

or small flakes) - Cashews

- Chia seeds

- Chickpeas

- Small chocolates

- Chocolate chips

- Corn nuts

- Dried meal worms

and grubs - Dry cat food

- Dry dog food

- Feed pellets

- Fertilizer pellets

- Fish food (small

flakes and pellets) - Glass beads

- Granola

- Grass seeds

- Hard candy

- Hop pellets

- Jimmies

- Popcorn Kernels

- Kibble

- Legumes

- Millet

- Mixed seeds

- Mushroom substrate

- Pasta (small)

- Peas (dried)

- Peanuts

- Pecans

- Pistachios

- Plant food

- Rice

- Seeds

- Sprinkles

- Sunflower seeds

- Walnuts and

ground walnuts - Tablets

- Tea (dry)

- Wax beads

- Wood pellets

- Whole corn or plastic pellets for filling cornhole bags or bean bags

- Fill Rate: 480-900 bags, stand up pouches, or containers per hour with a +- ½ to 1% accuracy depending on the product

- Max Fill Weight: 22 lb (10kg)

- Included: 2 cubic foot supply hopper, epoxy coated mild 10-guage steel construction, one Syntron® electromagnetic vibrating feeder (IP66, 6" x 30" stainless steel trough), 0.3 cubic foot capacity product weigh hopper (8.45 liters), Rice Lake 880 programmable scale controller (NEMA 4X/IP69K), single scale with foot pedal activation, multiple spout and chute sizes available

- Materials of Construction Options: mild 10-guage steel (standard), stainless steel product contact surfaces, all stainless steel, all stainless steel for food grade applications

- Available as a Tabletop Filling Machine (no hunching over on ground or stool to fill):

- 41.5” height and 36” x 46” tabletop space

- Raise the height with a standing leg kit and casters (105” height and 36” x 46” floor space)

- Stainless steel tables are available for purchase

- Optional Upgrades: 304/316 stainless steel construction, second scale and vibratory feeder for faster fill rates, standing leg kit, casters, 3.5 cubic foot hopper, hopper lids, optional platform in the back of the machine to load the hopper, bucket elevators / feeders, and more

Images

Click a thumbnail below for a larger image.

Need help fast?

Use our Express Contact Form to get a custom quote from our sales engineers usually in 24 hours or less!Call: (979) 217-1480

Models S600 through S1500 – Small Bag Filling Machines (Up to 30+ Bags, Stand Up Pouches, or Containers / Min)

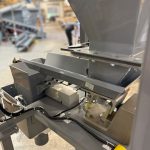

This type of small bag filling machine quickly fills bags and pouches with 1-25 lbs. of dry, free-flowing products. The standard small net weigh bagging scale includes a gravity gate, single vibrating pan feeder, and a weigh hopper that is suspended from a single load cell. It is available in simplex, duplex, and triplex configurations for high speed commercial packaging systems.

Add an auger feeder for fluid products or interface with vertical or horizontal form, fill, and seal machines. Stainless steel product contact surfaces or food-grade stainless steel construction are available, as well as dust tight spouts and enclosures.

Simplex scale configuration: Up to 12 bags per minute (600 bags per hour)

Duplex scale configuration: 20+ bags per minute (1,100 bags per hour)

Triplex scale configuration: 30+ bags per minute (1,500 bags per hour)

Accuracy: +/- 0.5-1% of target weight

Bag weight range: 1-25 pound bags (0.45-2.26 kilograms)

Bag types: pre-formed open mouth bags, stand up pouches, or doypacks constructed of paper, plastic, or poly-woven materials

Need automation? Add an automatic bag placer!

- aquarium gravel and specialty aggregates

- almonds

- bird seed

- cashews

- cat food

- chia seeds

- chicken grit

- coffee beans

- cover crop seeds

- dog food

- dried fruits

- grains

- grass seed

- ground coffee

- hop pellets

- peanuts

- plastic pellets

- small feed pellets

and poultry feed - rice

- seeds

- sugar

- sunflower seeds

- test plot seeds

- water filtration products

- wood pellets

- and more

- Included: gravity gate feeder with pantleg diverter to an Eriez electromagnetic vibratory pan feeder, 0.4 or 1.0 cubic foot capacity weigh hopper, single point compression load cell, Systec digital controller with memory retained recipe codes and data collection capabilities

- Choose: simplex, duplex, or triplex scale; construction material, bag spout with size: straight spout without bag clamp, center grip spout, dust tight spout, clam shell spout all with foot pedal controls for clamping and discharge

- Materials of Construction Options: : mild 10-guage steel (standard), stainless steel product contact surfaces, all stainless steel, all stainless steel for food grade applications

- Optional Upgrades: : auger feeder for flour, powders, or other fluidic products; dust tight enclosures; multi-dump feature for double discharge of larger bag weights greater than internal weigh hopper capacity; micro ingredient system for 1 pound or less weighments

- Compressed air: required

- Electrical: 1 or 3 phase

- Dust Collection: optional

Images

Click or tap a thumbnail below to view a larger image.

Watch a Video:

Need help fast? Use our Express Contact Form

Call: (979) 217-1480