« Equipment and Systems

-

- Small Bag Filling Machines

- Open Mouth Bagging Machines

- Valve Bag Filling Machines

- Automatic Bag Placers

- Bulk Bag Filling

- Bulk Bag Unloaders

- Bag Sewing Machines

- Bag Sealing Equipment

- Bag Handling Conveyors

- Manual Palletizing Systems

- Robotic Bag Palletizers

- Gantry Palletizer Systems

- Automated Pallet Wrappers

- Automatic Bagging

Machines & Systems - IBC Blending

- Stainless Steel Intermediate Bulk Containers

Automatic Bag Placers

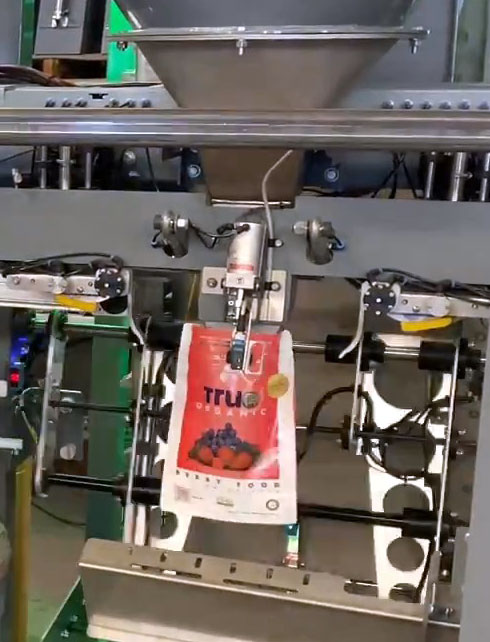

Automatically place stand up pouches, open mouth bags, and valve bags on filling machine spouts.

Automatic bag placers are designed to pick up empty bags or stand-up pouches and place them onto a bag filling machine’s spout. They can operate as part of a fully automatic bagging system or function as standalone robotic units that also perform additional tasks such as palletizing filled bags.

These systems are commonly used to increase production speed and reduce labor costs by replacing one or more manual operators. They integrate seamlessly with other downstream equipment such as bag sewing, sealing, or conveying systems. This creates a continuous, fully automated packaging process.

Watch a Video: Placing Small Bags and Stand Up Pouches

Watch a Video: Placing Large Open Mouth Bags

Watch a Video: NEW! All-in-One Robotic Valve Bag Placer AND Palletizer

Click a link below to jump to a section on this page:

- Stand Up Pouch Placer (15+ pouches/min)

- Open Mouth Bag Placer (15+ large bags/min)

- Valve Bag Placers (10-15 bags/min)

Call: (979) 217-1480

Need to fill larger bags weighing 20-110 pounds? View the Open Mouth Bagging Machine or Valve Bag Filling Machine pages.

Stand Up Pouch Placer (15+ pouches/min)

An empty pouch is conveyed from a magazine toward a mechanical arm. The arm retrieves the empty pouch, swings up, and places it on the filling spout. Once the pouch has been filled, a transfer arm retrieves the filled pouch and places it onto a closing conveyor where it is conveyed into a heat sealer.

Note: Pouch filling rate will depend on the material and final pouch size.

Features

- Designed for small pouch and bag weights from 2 to 22 lbs. (approx. 1–10 kg)

- Handles PE, BOPP, paper, or Mylar bag materials

- Accepts pillow or side-gusseted bag styles

- 15+ pouch per minute production speed (depends on material and pouch size)

- Auto bag-size adjustment for quick changeovers

- Gusset reforming system for precise bag presentation

- Adjustable bag spout (multiple spout sizes available)

- Bag tamping support plate ensures stable placement

- Servo-driven pneumatic bag transporter for smooth, accurate movement

- Fully integrated PLC/HMI operator interface for easy control

- Includes complete electrical and pneumatic package

- Safety cage and safety relays for operator protection

Specifications

- Pouch and Bag Weight Range: 2–22 lbs. (1–10 kg)

- Pouch and Bag Widths: 5.5”–14” (140–355 mm)

- Pouch and Bag Lengths: 10”–25” (254–635 mm)

- Magazine Capacity: 300 empty pouches or bags

- Drive & Controls: Servo motors with feedback, Schneider controls, Piab vacuum, and Asco pneumatics

Images

Click or tap a thumbnail below to view a larger image.

Watch a Video Demonstration

Need help fast?

Use our Express Contact Form to get a custom quote from our sales engineers usually in 24 hours or less!Call: (979) 217-1480

Open Mouth Bag Placer (15+ bags/min)

For open mouth bags or larger pouches, an empty bag is retrieved from a stack of bags by a robotic arm and placed or conveyed onto a staging tray. Then, the automatic bag placer’s arm swings down and picks up the bag and places it on the bag filling machine’s spout. After filling, a transfer arm moves the filled bag into a bag sewing or sealing system.

Note: Bag filling rate will depend on the material and final bag size.

Features

- Designed for open mouth bags from 20 to 50 lbs. (approx. 10–25 kg)

- NEW! Integrated Fanuc ER-35 robotic arm with precision bag-gripper tooling and empty bag magazine - Note: The robot is mounted inverted (upside down) to maximize speed and positioning accuracy.

- Handles PE, BOPP, paper, or Mylar bag materials

- Compatible with pillow or side-gusseted bag styles

- Up to 15+ bags per minute production speed (depends on material and final bag size)

- Automatic bag size adjustment for quick changeovers

- Gusset reforming system for proper bag alignment

- 8” clam-shell bag spout for secure fill positioning

- Larger vacuum cups and venturi system for reliable bag pick-up

- High-speed servo drive with gearbox for smooth 50-lb. bag transfer

- Servo-driven pneumatic bag transporter ensures accurate placement

- Fully integrated PLC/HMI operator interface for easy control and monitoring

- Includes complete electrical and pneumatic package

- Safety cage and safety relays for full operator protection

Specifications

- Bag Weight Range: 20–50 lbs. (10–25 kg)

- Bag Widths: 11”–18” (279–457 mm)

- Bag Lengths: 24”–38” (610–965 mm)

- Bag Magazine Capacity: Large-capacity empty bag magazine

- Robot System: Fanuc ER-35 robotic arm with gripper tooling

- Drive & Controls: Larger servo drive with gearbox, servo motors with feedback, Schneider controls, Piab vacuum, and Asco pneumatics

Images

Click or tap a thumbnail below to view a larger image.

Watch a Video Demonstration

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Valve Bag Placers (10-15 bags/min)

These valve bag placers are designed for efficient, reliable placement of valve style bags onto filling machines. Available in several configurations from a compact single-arm model to multi-arm and fully robotic all-in-one systems, each version is built for precision, flexibility, and continuous operation in automatic packaging systems.

Stacks of 20-50 empty valve bags are loaded into an empty bag magazine. Then a device removes a bag from the top of the stack and opens the valve on the bag. An arm or robotic valve bag placer swings over and retrieves the empty valve bag and places it on the valve bag filling machine’s spout. After filling, the valve bag is automatically tilted backward and discharged onto a heavy duty wire mesh conveyor. Robotic valve bag placers can also palletize the filled bags after they discharge onto a conveyor.

Note: Bag filling rate will depend on the material and final bag size.

Features

- Handles bag weights from 5 to 50 kg (11–110 lbs)

- Compatible with paper, PE, laminated PP, and paper with PE lining or interior PE bag

- Supports pillow, side-gusseted, and valve-style bag formats

- Production speeds up to 10-15 bags per minute per spout (depending on material, bag size, and system configuration)

- Single or multi-arm designs for one to four filling spouts

- Robotic pick-and-place systems available for automated bag loading and palletizing

- Ultrasonic valve sealing for airtight, dust-free closures

- Automatic bag-size adjustment and interchangeable nozzles for flexible operation

- Large-capacity bag magazines for extended run times

- Servo-driven pneumatic bag transporters for precise bag placement

- Fully integrated PLC/HMI control system with intuitive operator interface

- Compact footprint with modular, easy-to-install design

- Safety cage and relays to ensure operator protection

- Low-maintenance construction using Schneider controls, Piab vacuum, and Asco pneumatics

- Optional automatic pallet placement and slip sheet application on robotic models

Specifications

- Bag Weight Range: 5–50 kg (11–110 lbs)

- Bag Widths: 350-600 mm

- Bag Lengths: 400-800 mm

- Bag Magazine Capacity: Up to 300 bags (depending on configuration)

- Max Output: Up to 500 bags/hour per spout

- Pallet Height (robotic models): Up to 1,600 mm (including pallet)

- Installed Power: 3-12 kW (robotic models up to 10 kW)

- Air Consumption: 8-17 Nm³/h

- Weighing System: Gross weight configuration for high accuracy

- Construction: Heavy-duty frame with accessible maintenance points

- Options: Ultrasonic valve sealing, multiple bag magazines, automatic pallet placement, and configurations for corrosive or explosive materials

Images

Click or tap a thumbnail below to view a larger image.

Watch a Video Demonstration

Need help fast? Use our Express Contact Form

Call: (979) 217-1480