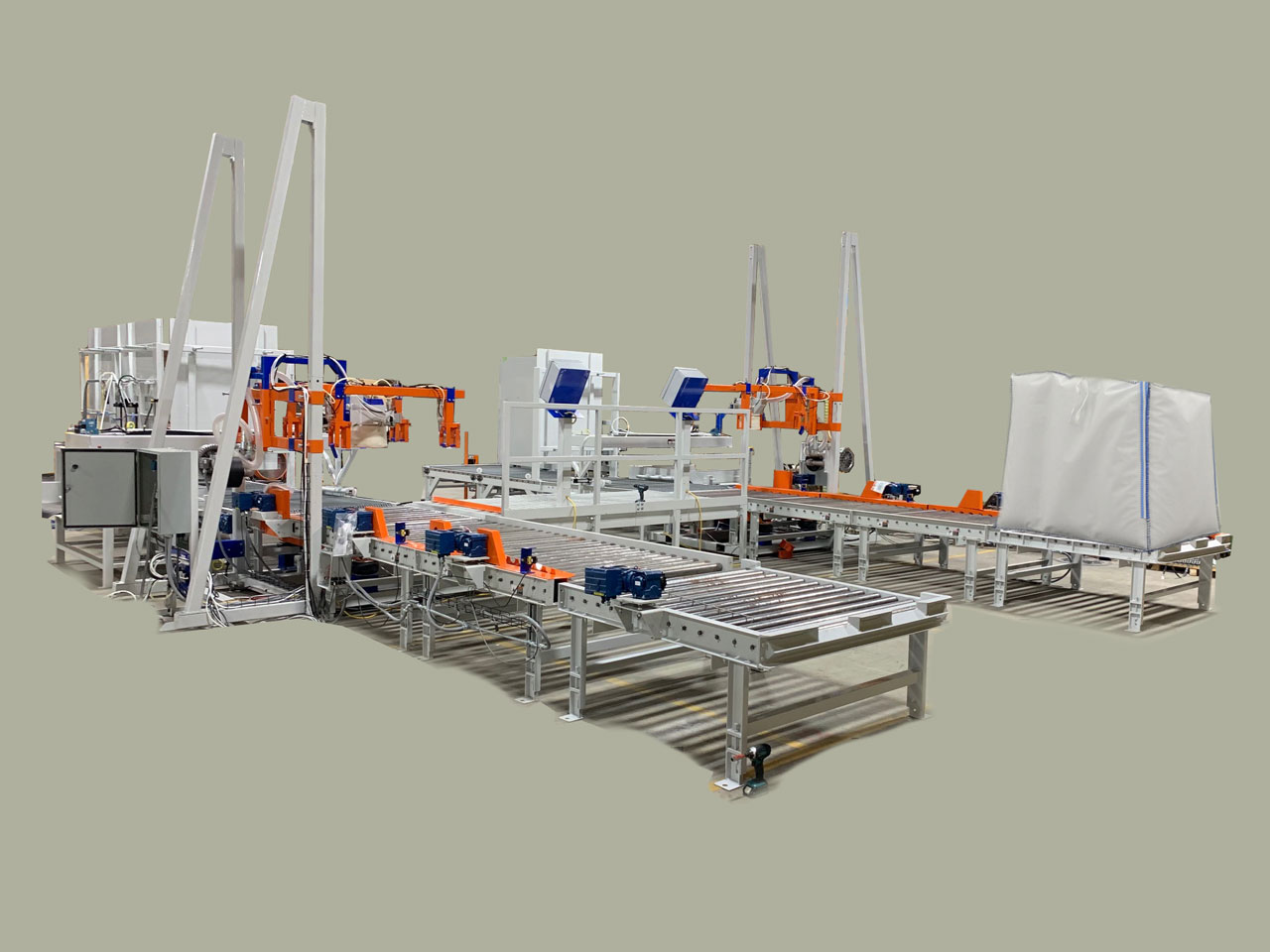

These dual bulk bag fillers efficiently fill big bags with raw material such as sand, cement, bentonite, plastic pellets, fertilizer and more at a rate of 20-25 bags per hour. A single pallet is discharged from the pallet dispenser. A slip sheet dispenser then applies a slip sheet on top of the empty pallet before it is loaded in to the filling station. Bag filling starts with a push of a button and bag is filled to set target weight. Final product is conveyed to end of the line where a robotic forklift moves the bag to a warehouse for storage and shipping.

System includes:

- Dual bulk bag filling station with inflatable fill head, dust collection port, inflatable bag blower, vibrating table deck, bag strap release and elevated platform with central controls

- Pallet dispenser system

- Slip sheet dispenser

- Power outfeed roller conveyor with filled bag accumulation table

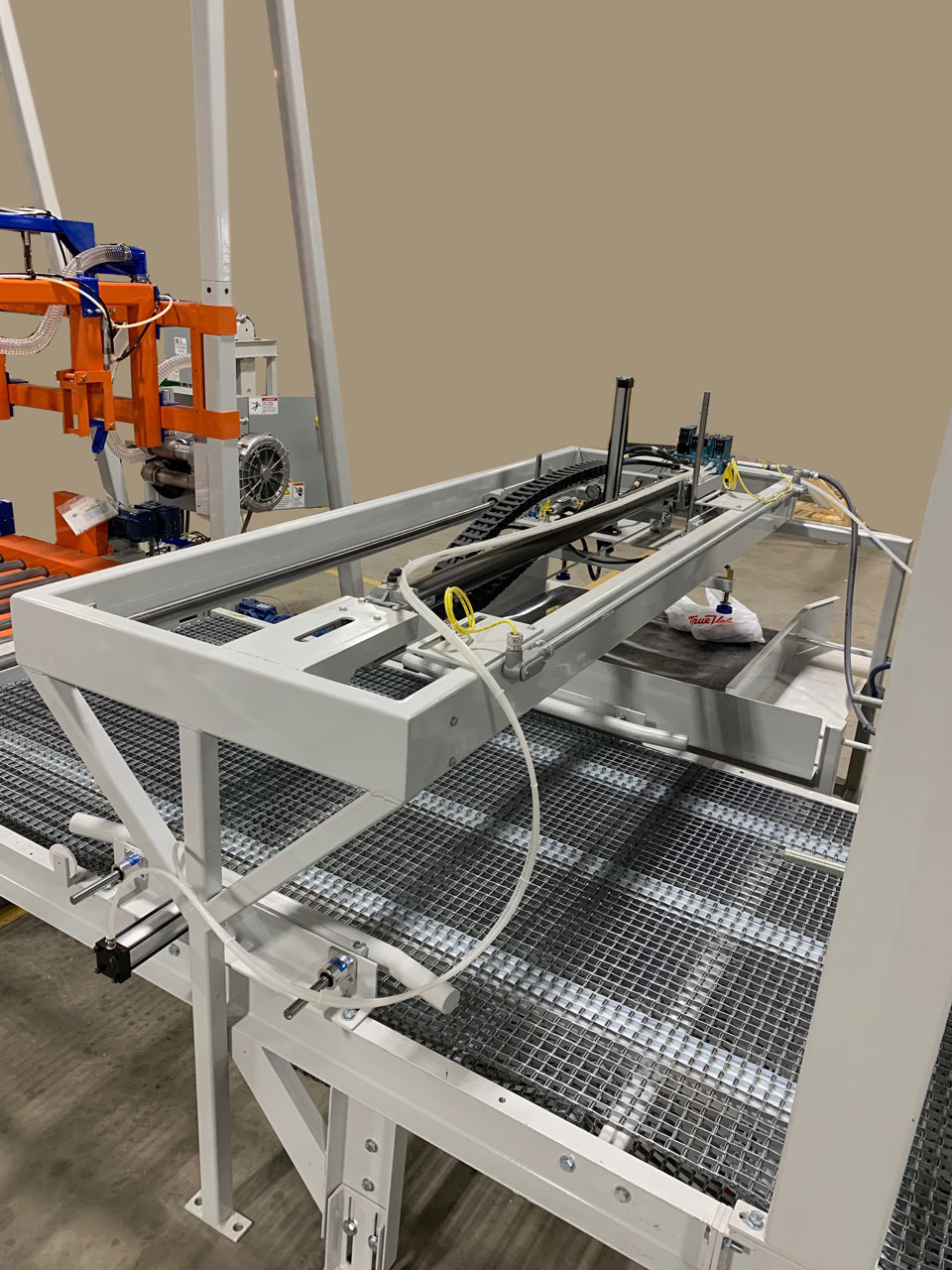

Auto adjustable fill head and strap clamps – Section lowers down for empty bag attachment and then raises up to allow for filling of the bulk bag. Straps are auto released when bulk bag is filled.

Auto slip sheet dispenser – slip sheets are added to the pallet.

Pallet dispenser – The short conveyor section on the right side is the area for the forklift to drop off a stack of pallets 10 to 12 high. The next section to the left, with the forks, is the pallet dispensing section. The forks retract backwards, lifts up and then down to dispense one pallet at a time.

View more Bulk Bag Filler case studies

Ask a question or get a price quote.