« Equipment and Systems

-

- Open Mouth Baggers

- Valve Bag Filling Machines

- Bulk Bag Filling Machines

- Bulk Bag Unloaders

- Bag Sewing Machines

- Bag Sealing Equipment

- Bag Handling Conveyors

- Manual Palletizing Systems

- Robotic Bag Palletizers

- Gantry Palletizer Systems

- Automated Pallet Wrappers

- Automatic Bagging

Machines & Systems - IBC Blending

- Stainless Steel Intermediate Bulk Containers

Large Feeders

Custom engineered vibratory feeders for industrial applications

These large vibratory feeders are used for dispensing abrasive, high temperature bulk solids and materials to downstream processing equipment. Feeding rates can be fixed or variable depending on processing requirements and as high as 1,000 tons per hour.

Vibratory pan feeders utilize a solid pan surface. They can also integrate screening or scalping to the pan surface to remove unwanted particles at the same time. Typically, a feeder will draw product from a dump hopper located above the vibrating feeder pan. These large vibratory feeders can be totally enclosed or utilize a vibrating tube feeder design.

We offer medium duty or very large, heavy duty vibratory feeders for any application. Drive options include electromagnetic or electromechanical (rotary electric) drives, as well as pneumatic vibrator drives.

Available Models

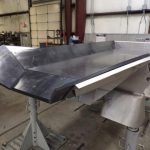

Vibratory Pan Feeders

These large vibratory pan feeders are used at truck dump stations, under bin / hopper discharge, railcar unloading stations and at crusher feeding locations. Their heavy-duty, single-mass design eliminates maintenance and fine tuning of typical two-mass systems. All large vibratory pan feeders can be custom designed and engineered to meet your project's requirements.

- Feed materials precisely at rates up to 4,000 tons per hour using excellent control packages

- Simple, rugged design eliminates exciter springs and tuning problems

- World-class electromechanical drives with explosion-proof certification available

Images

Click or tap a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

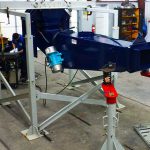

Vibrating Tube Feeders

These large vibrating tube feeders convey material horizontally through a fully enclosed environment at a controlled feed rate. All vibrating tube feeders use a gentle conveying motion that results in nearly no degradation or damage to the conveyed material. Tube feeders are primarily used in applications where dust control and sanitation are critical. Dust tight covers and inspection hatches allow easy access and clean out.

- Dust free feeding of material

- Low maintenance with no internal moving parts

- Easy-to-clean with dust-tight inspection hatches and covers

- Explosion proof certification available

Images

Click or tap a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480