« Equipment and Systems

-

- Open Mouth Baggers

- Valve Bag Filling Machines

- Bulk Bag Filling Machines

- Bulk Bag Unloaders

- Bag Sewing Machines

- Bag Sealing Equipment

- Bag Handling Conveyors

- Manual Palletizing Systems

- Robotic Bag Palletizers

- Gantry Palletizer Systems

- Automated Pallet Wrappers

- Automatic Bagging

Machines & Systems - IBC Blending

- Stainless Steel Intermediate Bulk Containers

Vibrating Tables

Vibrating tables for testing, compacting, settling, and shaking

These large vibrating tables settle materials in molds, boxes, packaging containers, drums, totes, gaylords, big bags, and more. They are also used as pallet shakers, as well as for vibration and fatigue testing in laboratories. All tables are engineered and built using high quality components, welds, and structure that allow them to operate consistently with very low maintenance for many years.

All vibrating tables can be custom built to meet your project requirements.

Available Models

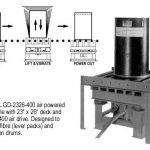

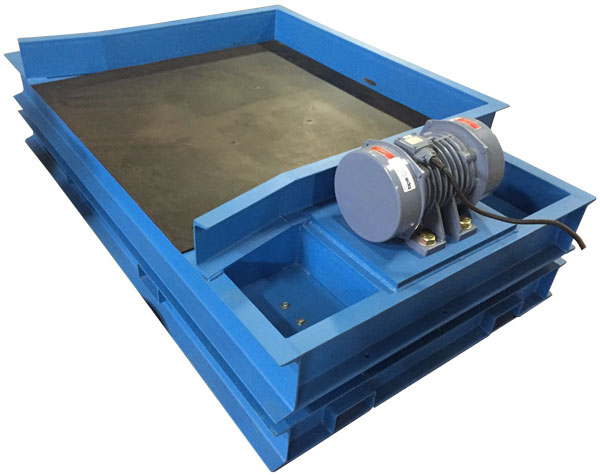

Flat Deck Vibrating Tables

Flat deck vibrating tables are available in air-powered or electric-powered versions and can be used to settle or compact materials in molds, bulk bags, bulk boxes or drums. They also can be used to remove air from concrete, resin and foundry casting molds.

Both the air-powered and electric powered vibrating tables provide a consistent up and down, linear vibrating action required for the best compaction and densification of product contents. The vibration intensity of both types can also be adjusted by regulating the air flow to the vibrator or by using an optional variable speed inverter type AC motor controller for remote variable RPM control.

Standard table sizes range from 12" x 12" to 48" x 48" and load capacities of 100 lbs. to 5,000 lbs.

Optional features include manual and automatic controls, load cells, and more.

- Twin electric

vibrating motors - Air vibration isolation mounts -or- coil springs

- Filter regulator

- Air piston vibrator

- Air vibration isolation mounts

- Filter regulator lubricator

Images

Click a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

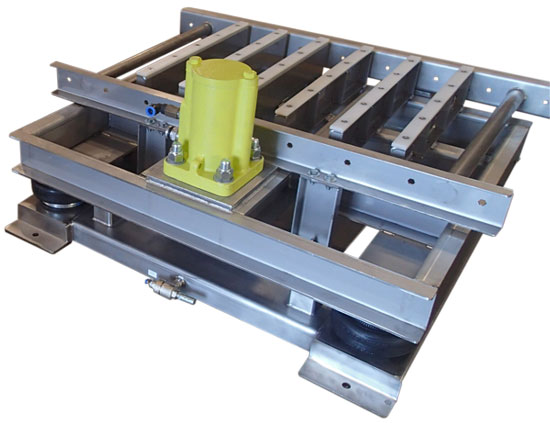

Grid Deck Vibrating Tables

Grid deck vibrating tables settle and compact products in drums, boxes, and containers as they pass over rollers on conveyor systems. They also shake pallets with large bulk bags or containers on them.

Empty containers are rolled into position over the grid deck vibrating table, which is in the lowered position. The container is then filled using a hopper-type net weigher or bulk filling station. Then the grid deck is raised by inflating the air mounts and the load is elevated off the roller conveyor surface. The industrial vibrators are turned on and the contents are compacted or "settled" inside the container. Upon completion of the vibrating cycle, the container is lowered back onto the roller conveyor and advanced to the next operation.

This design eliminates the need to vibrate the roller conveyors and provides and effective, quiet, and fast way of filling containers to their maximum weight.

- Twin electric

vibrating motors - Air vibration isolation mounts -or- coil springs

- Filter regulator

- Air piston vibrator

- Air vibration isolation mounts

- Filter regulator lubricator

Images

Click a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480