This vibrating indirect cooling conveyor is used to cool thermally treated hazardous waste from 600°F to 200°F using water as the cooling medium. The conveyor is 5 feet wide by 50 feet long. The conveying trough uses deck plates with convoluted embossing, through which the cooling water flows to remove the heat from the hazardous waste. The cooling chamber is totally enclosed and vented. It is made of carbon steel and the industrial vibration motor uses a natural frequency design with a low HP.

What is indirect cooling?

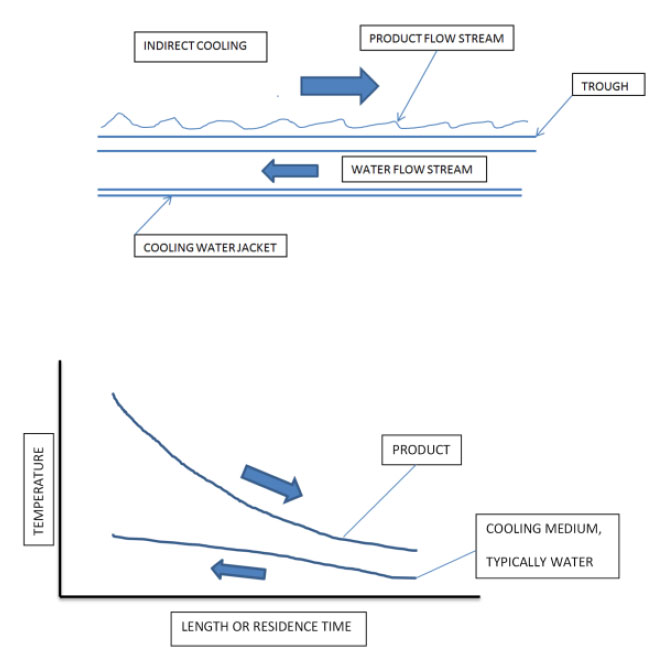

In an indirect cooling system, a hot material is conveyed along a vibratory conveyor trough surface that is cooled on its underside by a completely segregated cooling medium flow stream. The cooling medium “indirectly” absorbs the heat given up by the hot material as it moves along the length of the conveyor trough. Conversely, indirect heating can occur on a similar basis with hot water, steam, or other heated medium. Indirect cooling is usually applied when the material is oxygen sensitive or categorized as a hazardous waste.

Counter-flow of the two flow streams is typically used to improve heat transfer efficiency. Although water (or steam) is the most common cooling (heating) medium, aqueous solutions of ethylene glycol, heating oils, and other mediums can be used.

Construction may be carbon steel, stainless, or other metals.

Ask a Question or Get a Price Quote