Indirect cooling vibratory spirals incorporate very long cooling lengths and large surface areas for extended residence time for the cooling of air sensitive granular solids. These types of solids can include crumb rubber, granular chemicals, and food products, such as rice.

The large spiral conveyors incorporate a variable rate, two mass, natural frequency drive technology that allows for the fine tuning of the residence time for optimized cooling. The cooling chambers can be totally enclosed and conditioned with air or inert gas purged as the application requires.

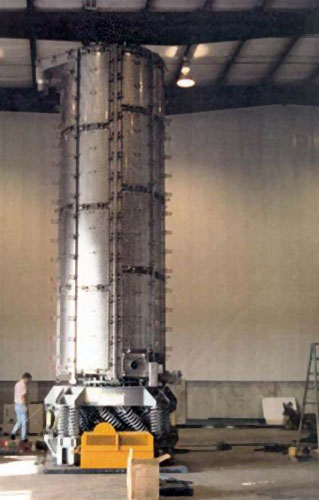

The cooling spiral as shown above is 78 inches in diameter with an overall lift of 21 feet. The conveyor is driven by (2) 3 HP industrial vibration motors. The spiral incorporates 240 square feet of cooling trough and 420 square feet of cooling surface area. It uses water flowing under the conveying trough for the cooling of the granular solids in the pan.

What is indirect cooling?

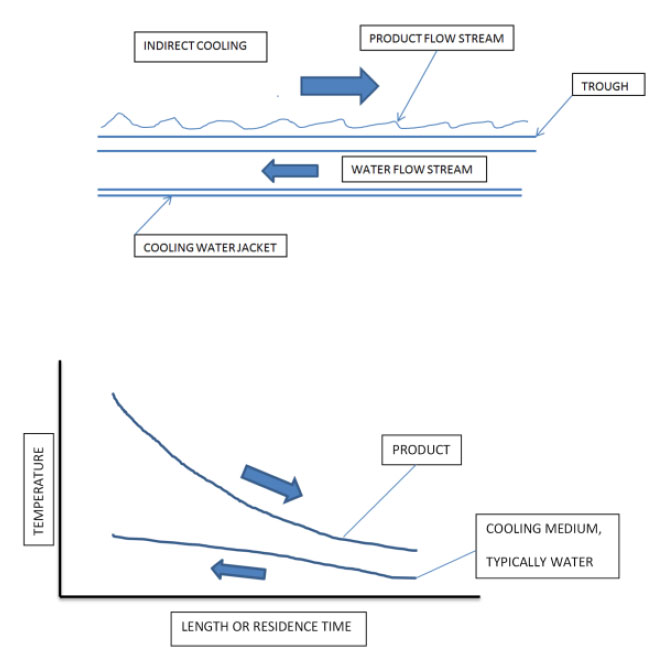

In indirect cooling, a hot granular material is conveyed along a vibratory conveyor trough surface that is cooled on its underside by a completely segregated cooling medium flow stream. This cooling medium indirectly absorbs the heat given up by the hot material as it moves along the length of the conveyor trough. Conversely, indirect heating can occur on a similar basis with hot water, steam, or other heated medium. Indirect cooling is usually applied when the material is oxygen sensitive or categorized as a hazardous waste.

Counter-flow of the two flow streams is typically employed to improve heat transfer efficiency. Although water (or steam) is the most common cooling (or heating) medium, aqueous solutions of ethylene glycol, heating oils, and other mediums are used as well.

Construction of the system may be of carbon steel, stainless steel, or other metals.

Ask a Question or Get a Price Quote