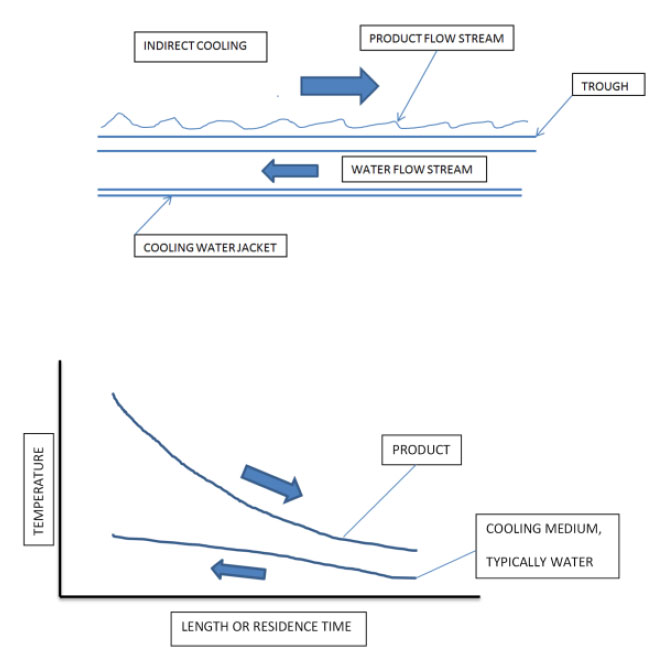

In this system, an indirect cooling vibratory conveyor is used to cool regenerated catalyst from 3,000°F to 300°F. This is done using 180°F cooling water obtained from a previous cooling step in the regenerative process.

A curvilinear trough cross section was developed to control the relative thermal expansion growth. A series of draped and contoured linked metal curtains of sufficient weight serve as flow inhibitors and distributors. They are used to displace, spread, and mix the granular flow stream frequently, as it proceeds down the length of the cooling chamber. This produces a consistent temperature profile and uniform product discharge. The conveyor system is totally enclosed and uses a natural frequency drive system with (1) low HP industrial vibration motor.

Ask a Question or Get a Price Quote