A silica sand wash plant required (4) dual motor vibratory screening machines. These linear-motion screens included high open area 25 mesh urethane screen panels. Spray nozzles were also incorporated into the design for increased fines removal.

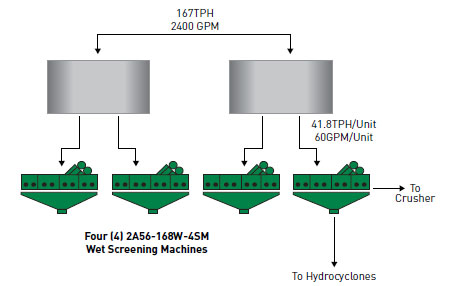

Silica sand is distributed evenly to the four screening machines which make a 0.7mm size separation. Oversize is conveyed to a crusher and undersize is pumped to a hydrocyclone stage for further processing.

The machines handle a silica sand feed rate of 167 TPH at 2400 GPM. There is high accuracy in controlling particle size separation and classification efficiency. Operating costs, including water consumption, are low. Electric power consumption, maintenance, and labor costs have also been reduced.

Ask a Question or Get a Price Quote