This industrial sand processing and sand washing equipment produces a clean and dry industrial sand that contains less than 2% -200 mesh at a rate of 150-175 t/h.

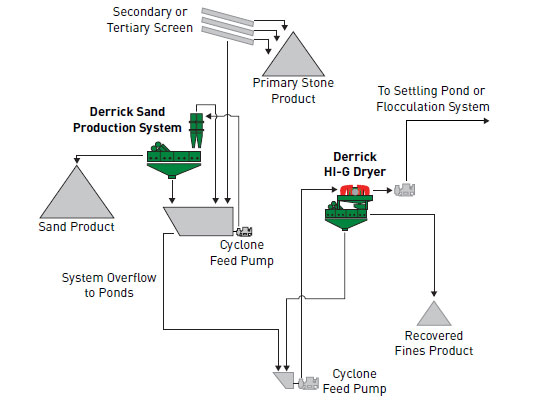

Slurry is pumped up to (2) 18″ maximum density separator units. These units provide a nominal cut point at the 200 mesh (75 micron) level. The newly recovered material is then fed to the hi-capacity dewatering screen at 50-52% solids by weight.

The linear motion and high “G” forces of the screen, along with the 1.4mm urethane screen panels, dewater the sand to a remarkable 90% solids by weight. Dual spray bars on the dewatering screen clean the sand of fines, which increases the value of the product.

The Derrick Fines Recovery System was installed to recovery as much of the fines as possible discharging prior to entering the settling pond. This was to lessen the continuous pond maintenance costs. The dryer recovers down to the 400/500 mesh level and dewaters this fraction down to a very dry 80% solids.

Results:

- Produces superior, clean, and dry sand

- Contains less than 2% -200 mesh in the end product

- Daily production rate of 150-175 t/h

- Saves of $400,000 annually on drying costs (BTUs) at their sand production plant

- Hi-G dryer fines recovery system recovering 75% of plant waste material and converting it into a highly profitable product

Ask a Question or Get a Price Quote