A mineral sands producer used new vibratory screening machines (or repulping equipment) to recover garnet at over 90% efficiency. The older, conventional vibrating screens were only able to recover material at about 44% efficiency.

The mineral sands producer was using conventional vibrating screens in a 0.30mm screening application to produce two garnet-rich intermediate products in two sizes. Later processing required high screening efficiency in the wet circuit to recover the final garnet and other high value products. Unfortunately, a significant quantity of misplacement of size fractions, especially Garnet, continued to occur.

To overcome this problem, extensive testing was done at Derrick Corporation’s full-scale test lab in Buffalo, New York. The tests were highly successful and results indicated that less than 10% fines (-0.3mm) can be achieved in the oversize material using Derrick Repulp screens.

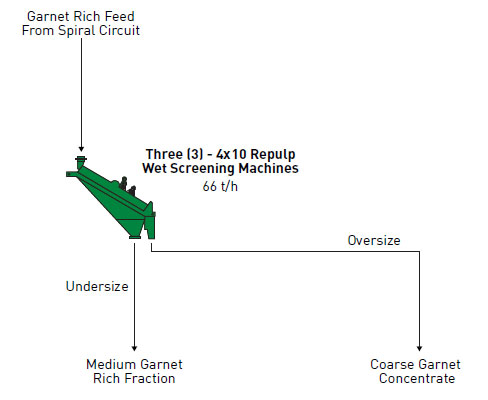

On the basis of the lab results, the mineral sands producer replaced the conventional screening equipment with (3) Derrick 4×10 Repulp screening machines.

Results

- Equipment is lighter, smaller, and more compact than previous screening machines

- Dramatic increase in coarse garnet production

- Cleaner product

- Less work by dry circuit

- Power consumption for (2) Derrick machines is less than was required for a single conventional screening machine

Ask a Question or Get a Price Quote