A large aggregate producer replaced an inefficient belt press and settling pond with a 12-15t/h Derrick® centrifuge and Hi-G® dewatering machine.

The belt press caused significant problems with fines recovery. Costs ran high because of numerous mechanical repairs, operating sensitivity, and excessive personnel time.

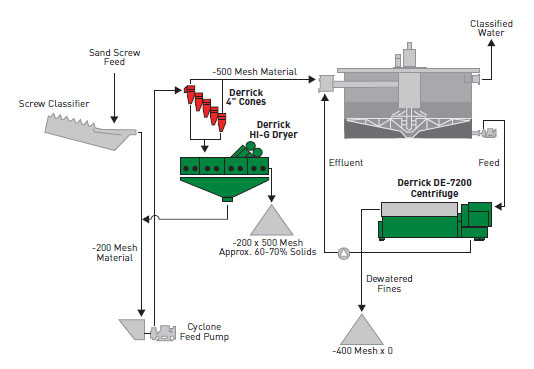

A Hi-G dewatering machine was installed. This is a combination of a hydrocyclone and high g-force dewatering screen. This unit recovers the +400 mesh (38 micron) size materials and converts them into a product that can be conveyed, stacked, and sold. This material accounts for approximately 60-70% of the solids present in the plant discharge slurry. The remaining 30-40% of the solids are sent to a high radial thickener device to consolidate the super fines and recover 95 percent of the water for return to the plant process. The challenge in handling the underflow from the thickener was the use of an obsolete belt press or plate-and-frame technology for dewatering.

To replace the outdated technology, a high capacity centrifuge was installed to handle the 12-15 t/h of thickener underflow at approximately 30% solids at 165 gpm. The centrifuge dewaters the super fines into a stackable conveyable form at 72% solids (by weight). The liquid effluent is returned to the plant process as a recirculating load.

Results

- Settling pond and belt presses eliminated

- All water is recovered from the thickener

- 100% of solids are dewatered

- Machines operate on small footprint

- No indoor or climate-controlled environment required

- No full-time operators which are needed for belt presses

- Significant cost reduction

Ask a Question or Get a Price Quote