This pneumatic conveying system is designed specifically for conveying hot abrasive ash, such as bottom ash (or fly ash) from boiler beds, baghouses, or electrostatic precipitators. These systems can handle temperatures up to 650°F (1,800°F with assembly) and can be arranged in a single line of 1 to 10 units. The Macawber pneumatic conveying systems also use about 50% less energy than typical fly ash conveying systems.

Watch a Video

Features

- Small equipment, easy to install

- Easily equipped for bottom dry ash

- Continuous cycling

- Fully automated

- Multiple pick-up or feed points on a single pipeline

- Excellent for retrofitting existing equipment because of low profile

- Very low cost per ton of ash transferred

- No moving parts, maintenance free

- Very low material transfer velocity-schedule 40 pipeline

- Installed worldwide since 1974

- ISO 9001 Certified

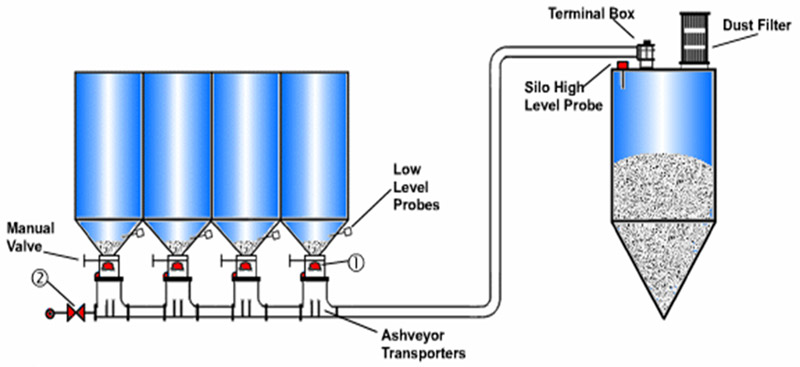

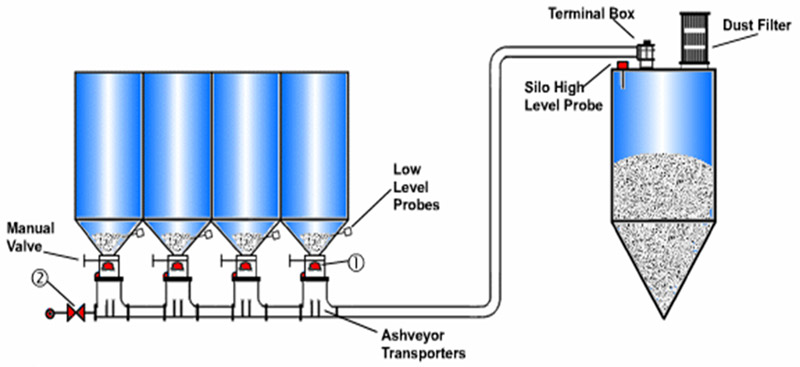

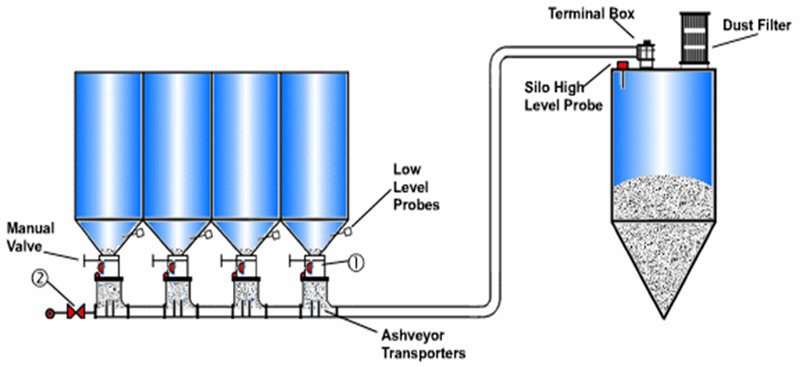

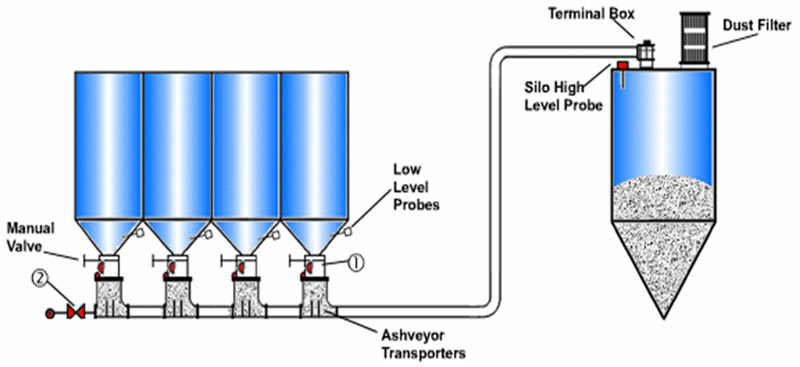

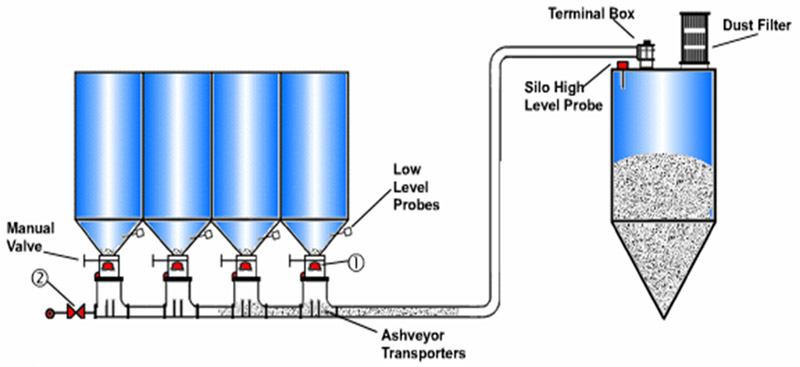

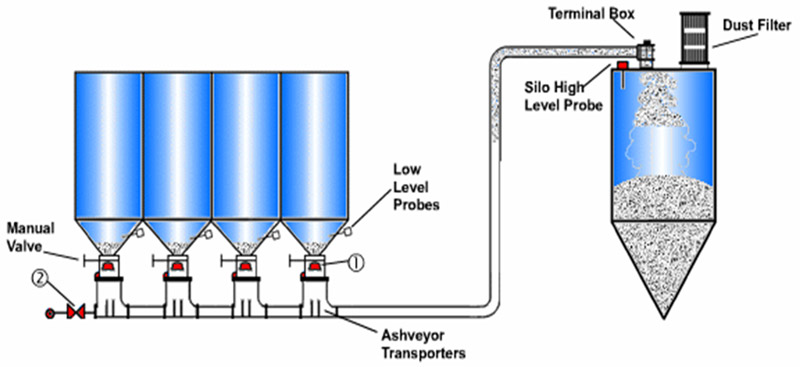

The Ashveyor’s small cast iron vessels do not require a vent valve, a level probe, or a discharge valve. Each cycle clears away deposited ash from the feed hopper, leaving them empty. Each line of the pneumatic conveying system, on each ESP field, economizer or baghouse cycle simultaneously transfers the ash through a common pipeline. Diverter valves for each feed point are not required and system controls are equally as simple.

Sequence of Operation

1. System at Rest

Pneumatic conveying system is waiting for sufficient ash to accumulate in the hoppers. Dome valves (1) are closed and sealed conveying air valve (2) is closed.

2. System Fill Cycle Commences

Ash has accumulated in the hoppers sufficiently to contact one of the level probes. All dome valves (1) open and unseal automatically. The air valve (2) remains closed.

3. System Filling

All dome valves (1) remain open during filling. Air valve (2) remains closed. Ash levels in hoppers fall, as the ash fills the Ashveyor transport vessels.

4. System Filling Complete

The Ashveyor vessels are now full. The hoppers are empty. The air valves (2) remain closed.

5. System Conveying Cycle Commences

All dome valves (1) closed and sealed. The conveying air valve (2) opens. The system pressurizes and the ash exits the Ashveyor vessels and enters the conveying line.

6. System Conveying

All dome valves (1) remain closed and sealed. Air valve (2) remains open. All of the ash is in the conveying line.

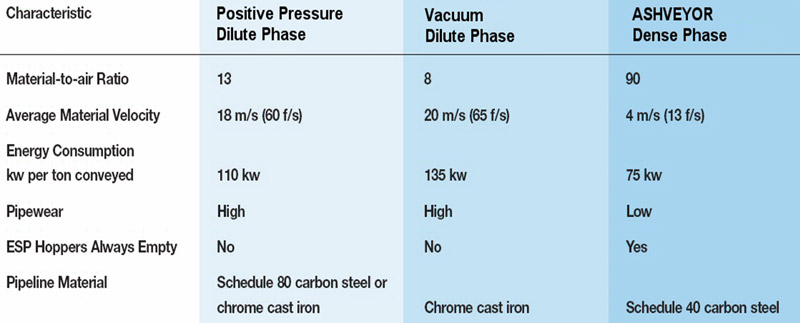

Ashveyor vs. Dilute Phase Conveying

Case Studies

Coal Gasification – SES, Shandong Prov., China (pdf)

Coal gasification is an upcoming clean coal technology, where the carbon materials in the coal are removed before the combustion process takes place. The gasification process is proven and is operational in several commercial plants worldwide. In the case of a customer, Synthesis Energy Systems, there was a need to handle waste material from the gasification process, while keeping the customer’s process pressure up. Macawber achieved this requirement with 2 x 8/8-4/8 Denseveyor Pressure Letdown systems for removal of the waste material originating from coal gasifier baghouses and electro-static precipitators. The systems were designed to operate at baghouse and ESP pressure for filling and then lock down to atmospheric pressure for conveying the waste material away to storage while maintaining process upstream pressure.

Biomass Ash Disposal – Grupo Modelo Brewery, Zacatecas Mexico (pdf)

A large brewery wanted to recycle waste grain and malt from the brew process for the production of electric power. Handling the biomass ash cleanly and economically was required.

Macawber pneumatic conveying systems were used to convey boiler bottom ash and fly ash away to storage. The biomass is dried and transferred to a boiler where it is burned with #6 oil. The biomass fly ash is gathered from four electrostatic precipitator (ESP) hoppers and pneumatically conveyed to an ash silo. The bottom ash is crushed and transferred a short distance via the customer’s mechanical conveyor to a pneumatic conveyor, where it is transferred to an ash silo for truck loading.

Pulverized Fuel Ash – Power Gen PLC (pdf)

Power Gen PLC of Retford, England relied on Macawber engineering at their Cottam Power Station (4×500 MW) to replace an existing fly ash handling system. The Macawber Ashveyor System was installed on unit #2 to continuously convey pulverized fuel ash (P.F.A.) over a distance of 560 feet.

Garbage Waste Ash – London-Waste, EcoPark (pdf)

The London Waste EcoPark is a 17ha site with a number of facilities used to reduce the amount of waste sent to a landfill. The power plant uses combustion to generate electricity from 500,000 tons of commercial and residential waste refuse per year on a continuous 24-hour operation.

London Waste purchased a total of 20 pneumatic conveying systems (four per ESP), with each system collecting the precipitator ash from custom hoppers and conveying it to the existing flue gas ash storage silos. All of the pneumatic conveying systems are Teflon coated for addressing the corrosive and cohesive nature of the precipitator ash caused by the absorption of moisture during the combustion process.

Ask a Question or Get a Price Quote