This vibrating fluid bed dryer is used to remove the surface and internal moisture from pre-crushed pumice. The ore enters the system via a belt conveyor and feeds the dryer. Air heated by natural gas is processed through the fluid bed dryer, removing the moisture. Moisture laden gas is sent to a dust collector to remove any entrained fines before the gas is released into the atmosphere. The dried ore is then discharged from the dryer onto a conveyor and sent to a storage silo.

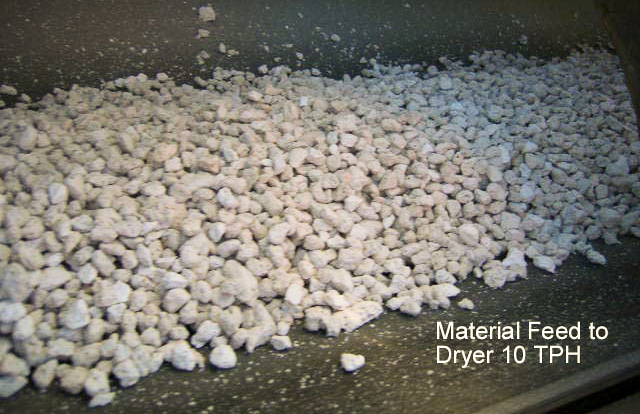

The vibrating fluid bed dryer uses a natural frequency drive system with a 5 HP industrial vibration motor for excitation of the drive system. Normal flow rate is 10 tons per hour and moisture in is 10% and out is 0.5%. The dryer is insulated and includes a complete system to control the gas temperature in the dryer and to provide flame safe guard protection to the gas burner.

Product discharge from the dryer onto a conveyor that sends it to a storage silo. Moisture is reduced in the pumice from 10% to 0.5% at a flow rate of 10 tons per hour.

Ask a Question or Get a Price Quote