A screening machine with two decks was built for a manufacturer of high density colorants used for plastic injection molding. They required the screen to remove longs and fines from the product flow that consisted of pellets. A second concern was to ensure that no ferrous particles like metal nuts, washers, bolts, or other foreign items got into the finished product. These types of tramp material could damage the expensive plastic injection molding machines.

A screening machine with two decks was built for a manufacturer of high density colorants used for plastic injection molding. They required the screen to remove longs and fines from the product flow that consisted of pellets. A second concern was to ensure that no ferrous particles like metal nuts, washers, bolts, or other foreign items got into the finished product. These types of tramp material could damage the expensive plastic injection molding machines.

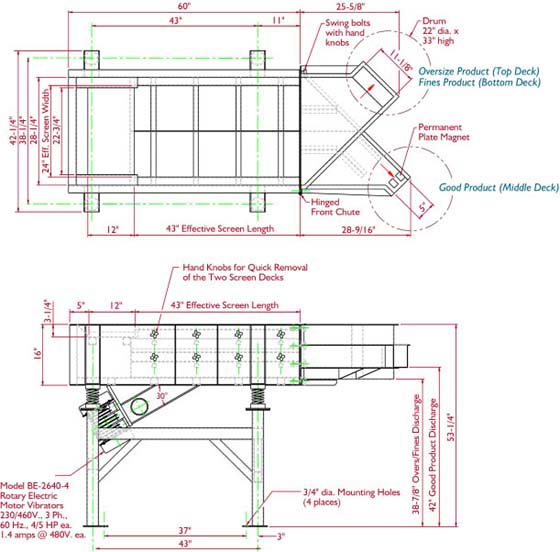

A two-deck twin motor vibratory screening machine was manufactured and installed. The main feature is the smooth, 1800 RPM non-upending action that prevents oversize longs from turning vertically and passing into the “good” product deck below. To ensure no product contamination, the entire body is manufactured from 304 Stainless and is fitted with magnetic separator to retain all ferrous particulates.

A quick removal front pivot chute and hand knobs provide quick screen size changes and easy cleaning for color changeover.