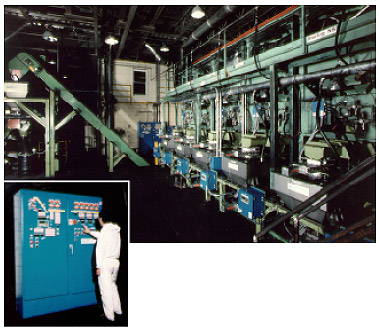

This batching system was custom designed for 7 types of carbon black. They are all simultaneously fed into individual weigh hoppers. Small vibratory feeders meter the carbon black into 16 cubic feet, net weigh hoppers supplied with air-operated, fast acting roller slide gates.

Upon discharge, an air-powered industrial vibrator cleans the weigh hopper before the gate closes. The batch is then transferred by belt conveyor to a 16 cubic feet confirmation (check weigh) hopper, where the final weight is either accepted or rejected. Accepted batches go directly into an industrial mixer. If a batch is out of tolerance, it is rejected via a pantleg diverter into a portable storage container at floor level.

Upon discharge, an air-powered industrial vibrator cleans the weigh hopper before the gate closes. The batch is then transferred by belt conveyor to a 16 cubic feet confirmation (check weigh) hopper, where the final weight is either accepted or rejected. Accepted batches go directly into an industrial mixer. If a batch is out of tolerance, it is rejected via a pantleg diverter into a portable storage container at floor level.

Target batches can vary from approximately 30 to 600 pounds, with final batch accuracy at +/- 0.5 pounds. Design feed rate is approximately 200 pounds per minute, with a product bulk density of 40-50 PPCF. This system is fully automated via a multiple recipe storage system. Loading of the carbon black into the system is via bottom dispensing 2,000 pound bulk bags, which are quickly unloaded into the process stream by big bag unloaders. The total modular and turnkey system was assembled and tested, component by component, on the manufacturer’s floor prior to final shipment.

New! Blending, batching, and mixing can now be accomplished inside IBCs using patented cone valve.