« Equipment and Systems

-

- Open Mouth Baggers

- Valve Bag Filling Machines

- Bulk Bag Filling Machines

- Bulk Bag Unloaders

- Bag Sewing Machines

- Bag Sealing Equipment

- Bag Handling Conveyors

- Manual Palletizing Systems

- Robotic Bag Palletizers

- Gantry Palletizer Systems

- Automated Pallet Wrappers

- Automatic Bagging

Machines & Systems - IBC Blending

- Stainless Steel Intermediate Bulk Containers

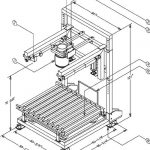

Bulk Bag Filling

Accurately fill and weigh any size bulk bag, bulk tote bag, drum, bin, or container. Choose from free standing bulk bag fillers, bulk bag filling stations, or completely automated filling systems.

Bulk bag filling machines quickly and efficiently fill bulk bags, or bulk tote bags, with a wide range of wet and dry bulk products. These machines can be permanent and placed under a hopper, or they can be portable and moved around from filling station to filling station.

Features

- Fill weights range from 1,000 - 2,200 pounds for standard, free-standing bulk bag fillers and up to 4,400 pounds for a bulk bag filling station with a pallet dispenser

- Adjustable bag heights from 42 inches to 60+ inches. Custom heights available upon request.

- Fill rates from 1-20 bags per hour for basic / mid-range fillers and up to 25 bags per hour with a pre-weigh bulk bag filler hopper

- Typical scale weight accuracy is +/- 0.5%-1% for basic / mid-range models and +/- 0.25-0.5% or better using a bulk bag filling station

- Control air 80 PSI at 1 CFM per bag filling cycle

- No electricity is required for basic free-standing bulk bag fillers. For bulk bag filling machines with scales and vibrating table decks, electrical requirements are 220 volt, 380 volt, 440 volt or 575 volt / 3 phase / 60 cycle.

- Recommended dust collection – 400 CFM minimum

Options

- Automatic conveyor infeed

- Bag detection

- Powered-fill height adjustment

- Inflatable bag seal cuff (fill head)

- Pre-fill bag inflator

- Vibratory table deck for bag densification

- Drum adapter for single drum or bucket loading

- Roller conveyor with vibratory grid deck for bag densification

- Automatic slip sheets and pallet dispensers eliminate manual pallet handling

- More custom options are available. Contact us for more information.

- Feed

- Corn

- Pellets

- Grains

- Seeds

- Grass Seeds

- Bird Seed

- Fish Feed

- Flour

- Rice

- Soybeans

- Barley

- Sugar

- Salt

- Spices & Seasonings

- Milk Powder

- Starch

- Sodium Bi-Carbonate

- Fertilizer

- PVC Resin

- Plastic Pellets

- Carbon Black

- Activated Carbon

- Gypsum

- Graphite

- Barite

- Bentonite

- Limestone

- Iron Oxide

- Zinc Oxide

- Titanium Dioxide

- Mortar Mixes

- Calcium Carbonate Powder

- And more!

Images

Click or tap a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480