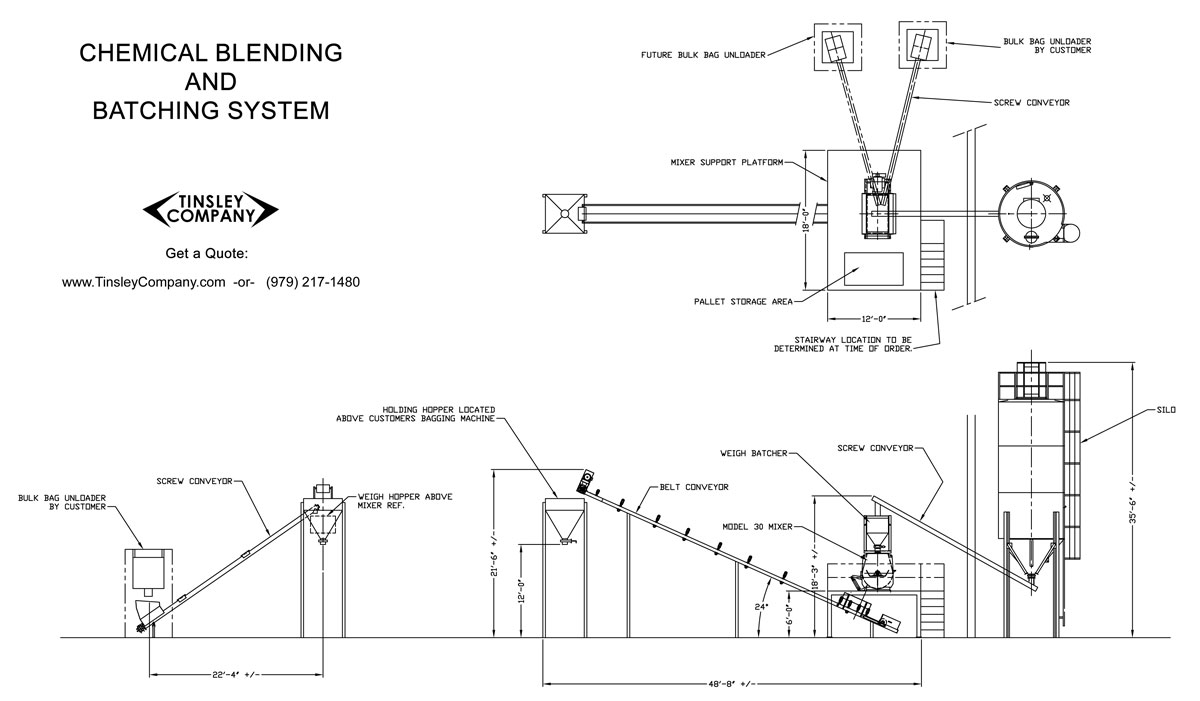

This chemical blending and batching system was used for the toll blending of powder chemicals, including calcium carbonate. The final blended product was to be automatically packaged into bulk bags using a bulk bag filling machine. It could also be packaged into smaller bags using a valve bagging machine.

The ingredients for this system were stored in an outdoor bulk storage silo, in bulk bags, and in paper bags. The storage silo contained calcium carbonate and the bulk bag unloader contained a proprietary chemical powder. The ingredients were moved in precise amounts from the storage silo and bulk bag unloader using a screw feeder. The screw feeder emptied the ingredients into a single shaft, industrial mixer. Other powdered chemicals were added from paper bags discharged into the top of the mixer. The mixer sat on top of load cells for weighing during the blending process.

After blending, a conveyor belt moved the blended material from the mixer to the surge hopper for packaging. The surge hopper had a 34-40 cubic foot capacity and max weight of 2,500 pounds. A bulk bag or valve bagging machine would be placed under the surge hopper for filling blended materials into bulk bags or valve bags.

Ask a Question or Get a Price Quote