Stack Sizer®, Dewatering Machines, and Polyweb® Urethane Screens Improve Frac Sand Production

Stack Sizer®, Dewatering Machines, and Polyweb® Urethane Screens Improve Frac Sand Production

- Eliminated dry sizing stage typically needed to meet quality specifications

- All products meet or exceed frac sand specifications

- Equipment flexibility allowed rapid response to revised marketplace demand for increased 40/70 production

Background

A startup frac sand plant in Arkansas, USA contacted Derrick® to evaluate the use of high speed vibrating screen machines for frac sand production. Familiar with the success of Derrick screens for fine sizing of iron ore and coal, the plant engineer believed that Derrick’s technology was critical to his process design. Derrick recommended Stack Sizers and Linear Motion dewatering machines for the application (Figure 1). All machines would be fitted with Polyweb® screen panels.

Solution

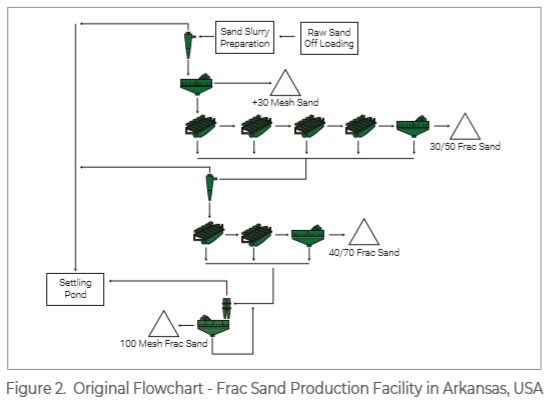

Using a Stack Sizer®, screening tests conducted at Derrick revealed particle size distributions ranging from about 3 percent +30 mesh (600 microns) to 15 percent -100 mesh (150 microns). These tests proved that in-spec 30/50 and 40/70 mesh frac sand could be produced by multi-stage wet screening (Figure 2). At the time of plant startup, maximum recovery of 30/50 frac sand was required.

The first stage of the process achieves maximum removal of +30 mesh (600 micron) particles by feeding four Derrick Linear Motion scalping screens with the 100 mesh (150 micron) sand slurry supplied by a hydrocyclone stage. The oversize solids are conveyed to waste piles, while the undersize fraction is collected and used as feed in the 50 mesh (600 micron) separation. This separation is accomplished by successive screening stages of the oversize fractions until at least 90 percent of the final oversize fraction is between 30 and 50 mesh. The 30/50 frac sand is then fed to three Derrick Linear Motion dewatering machines to reduce moisture content in the 30/50 product to 16 to 20 percent.

The combined undersize fraction from each 50 mesh (300 micron) screening stage is the feed for the 40/70 mesh product sizing. The 40/70 frac sand is produced in a multi-step process using Stack Sizers and dewatering machines, as is done for 30/50 frac sand production. After dewatering, the 40/70 product contains about 16 to 20 percent moisture.

The hydrocyclone overflow fractions from the 30/50, 40/70, and undersize 40/70 material from the Stack Sizers are combined to form the feed slurry needed for producing 100 mesh frac sand (Figure 3). Particle size distribution indicated that removal of about three percent of the residual –140 mesh (106 microns) material would produce 100 mesh frac sand. A large diameter hydrocyclone and additional Derrick Linear Motion dewatering machines are employed to remove the 140 mesh residue. Hydrocyclone underflow is fed to the dewatering machines, and overflow is directed to a settling pond. The dewatering machines produce 100 mesh frac sand containing about 16 to 20 percent moisture (Figure 4).

All three final frac sand products are conveyed from the dewatering machines to a covered outdoor storage area. As needed, each product is conveyed from the storage pile to a thermal drying unit. The dried product is then conveyed to a second storage building, where it remains until delivery to customers (Figure 5).

When the processing plant began operation in December 2016, demand for 40/70 product had already begun to exceed demand for 30/50 product. To meet the changing demand, coarser screen panels were installed on the Stack Sizers. The coarser panels pass approximately 100 stph (90 mtph) more material to the 40/70 module. Ultimately, the plant ceased production of 30/50 product, and plant changes were made to increase production of the 40/70 mesh product.

Solution

The efficacy of Derrick screening machines in frac sand processing has been demonstrated by this plant’s success. Stack Sizers, combined with Linear Motion dewatering machines and Derrick Polyweb urethane screen panels, are producing in-spec frac sand directly, without a dry sizing stage. Screen panel life on both Stack Sizers and Linear Motion dewatering machines has exceeded six months. The multiple Polyweb screen panel options have allowed production of frac sand that meets or exceeds specifications. Since startup, the plant has been processing approximately 225 stph raw sand to produce approximately 125 stph 40/70 mesh and 100 mesh frac sand. Plant optimization is ongoing in response to the changing demands of the frac sand market. Presently, Derrick Stack Sizer technology is included in a new optimization project to maximize production of the 40/70 mesh product.

Tinsley Equipment Company has been an Authorized Derrick Representative since 1990. Covering Texas, Oklahoma, Arkansas, and Louisiana.

Tinsley Equipment Company has been an Authorized Derrick Representative since 1990. Covering Texas, Oklahoma, Arkansas, and Louisiana.

Learn more about Frac Sand Solutions.

Ask a question or get a price quote.