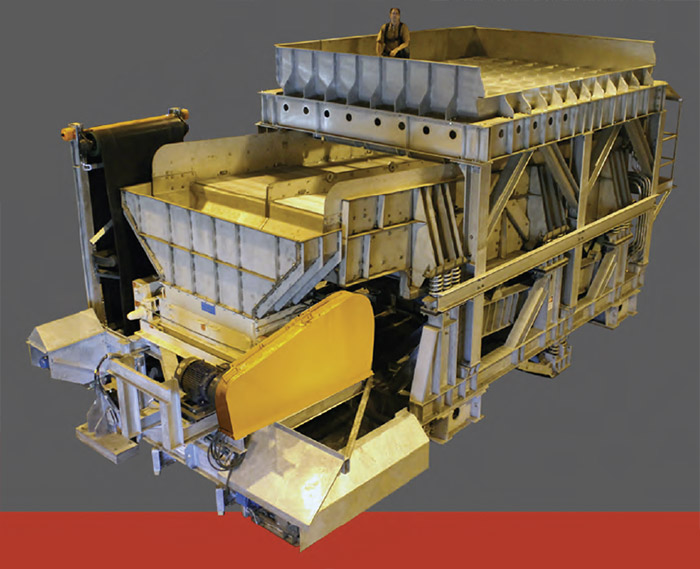

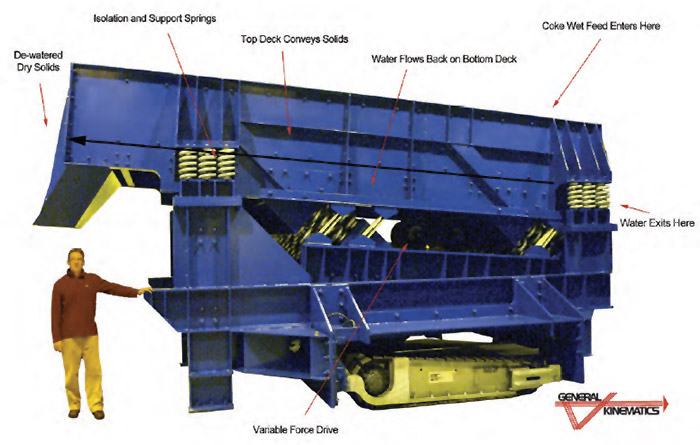

This continuous and automatic dewatering system turns wet petroleum coke slurry and sludge into dry solids that can be stacked or conveyed easily. The system requires little or no maintenance and is not affected by the amount of water in the solids. It can be stationary or mounted on tracks and rails.

This type of dewatering system fits most coking applications. It can also be used for other types of bulk solids that require industrial scale drying before loading onto rail cars, trucks, barges, or ground storage. It uses the principle of two-mass, natural frequency, sub-resonant magnification. This means that a small exciting force acts upon a coil spring amplification system to alternately store and release energy and move material in a shuffling motion.

Dewatering system features:

- It can be engineered for all types of bulk sludges and slurries

- Non-plugging design works without screens

- Solids rates from 350 to 800 tons per hour or higher upon request

- Water flow rates to 5,000 gallons per minute or higher

- Handles fines and “super” fines

- Accepts pieces up to 5 feet in diameter

- Energy saving two-mass vibratory drive system

- Heavy-duty stainless steel construction

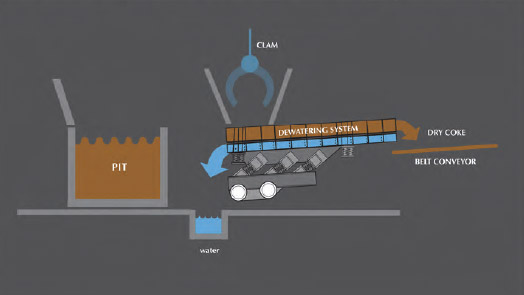

Pit side

Pit Side Arrangement

- Minimizes crane use

- Overhead clamshell bucket dumps wet petroleum coke into a hopper above the dewatering system

- Separated water flows into a sluice way or back into a pit for recycling

- Dry coke is deposited onto a belt conveyor for storage or loading

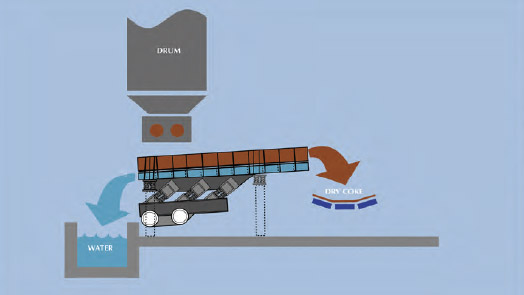

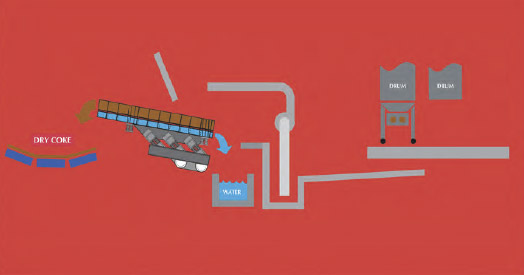

Under drum

Under Drum Arrangement

- Coking drum discharges through a special double roll crusher to the dewatering system

- Water is returned to the sluice way

- Dry coke is transferred onto a belt conveyor for loading or storage

Hydro sluice way

Hydro Sluice Way Arrangement

- Rail mounted double roll crusher deposits material into the sluice way

- The sluice way transfers water and coke into a sump

- Wet material sent to the dewatering system

- Removed water is returned to the sluice way

- Dry coke is transferred to a belt conveyor for loading or storage

Ask a Question or Get a Price Quote