Eight industrial vibrating tables were used to compact resin powder in boxes that were filled to a weight of 55 pounds per box. The customer wanted to reuse their existing packaging head to fill the boxes.

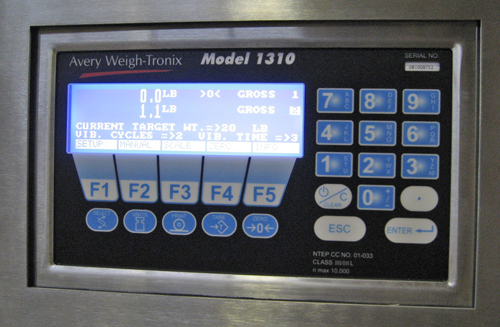

Each vibrating table has a powered roller deck, load cells to weigh each box, and controls to automate the box filling process.

Box Filling Process

An operator places a box on the roller deck and press the start button to initiate the filling cycle. When the start button is pressed, controls elevate the vibrating grid deck to compact the powder, while filling the box to the desired weight. Once the box has been filled, the vibrating grid deck lowers and the powered roller deck discharges the filled box onto a rolling accumulation conveyor. Each packaging line has a side-by-side system to allow one operator to fill two boxes simultaneously.

Ask a Question or Get a Price Quote