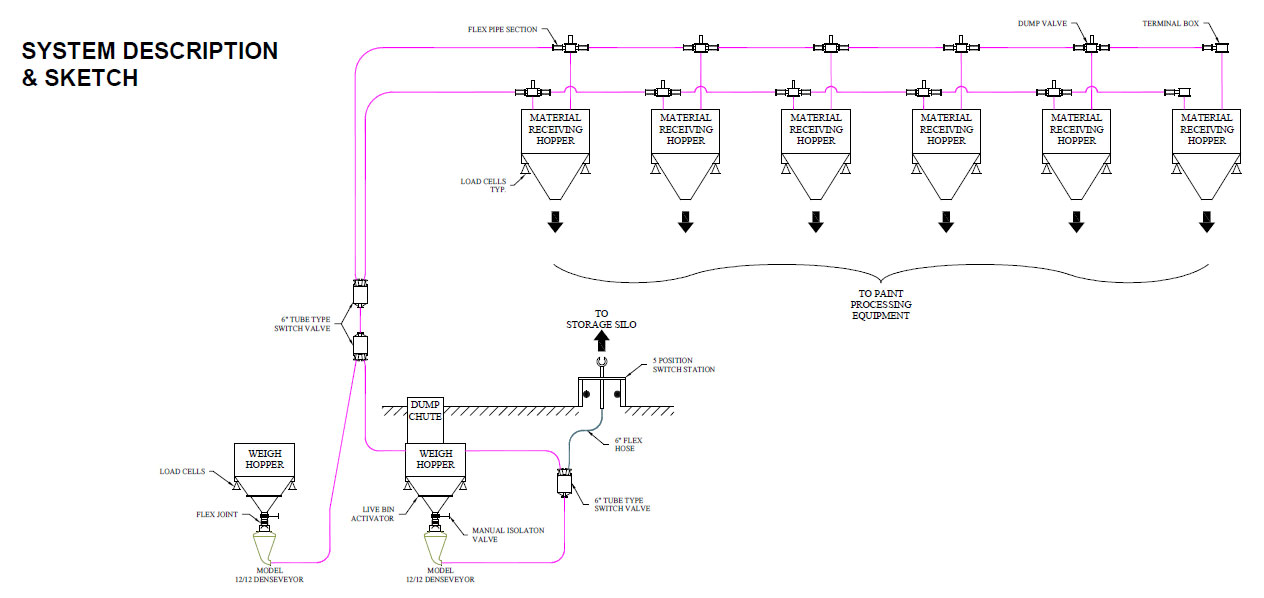

This pneumatic conveying system was installed at a paint production facility and was used to convey titanium dioxide over a distance of 400 feet to material receiving hoppers. It was also designed to pneumatically convey calcined clay, calcium carbonate, mica, amortized silica, and feldspar.

Titanium dioxide is a highly cohesive / adhesive powder containing agglomerated lumps. It tends to coat steel surfaces and is moderately abrasive. The powder in this case study had a moisture content of 1%.

A pneumatic conveyor (denseveyor) was designed, tested, and installed for smooth, efficient vessel filling and discharge. The vessel was filled using a dome valve. Pipeline boosters were not required.

The dense phase mode of conveying resulted in low pipe wear (the manufacturer provides no-wear guarantees for pipes and bends). It has a transfer capacity of 40 tons per hour over a distance of 400 feet to six reception points.

Watch a Video:

Ask a Question or Get a Price Quote