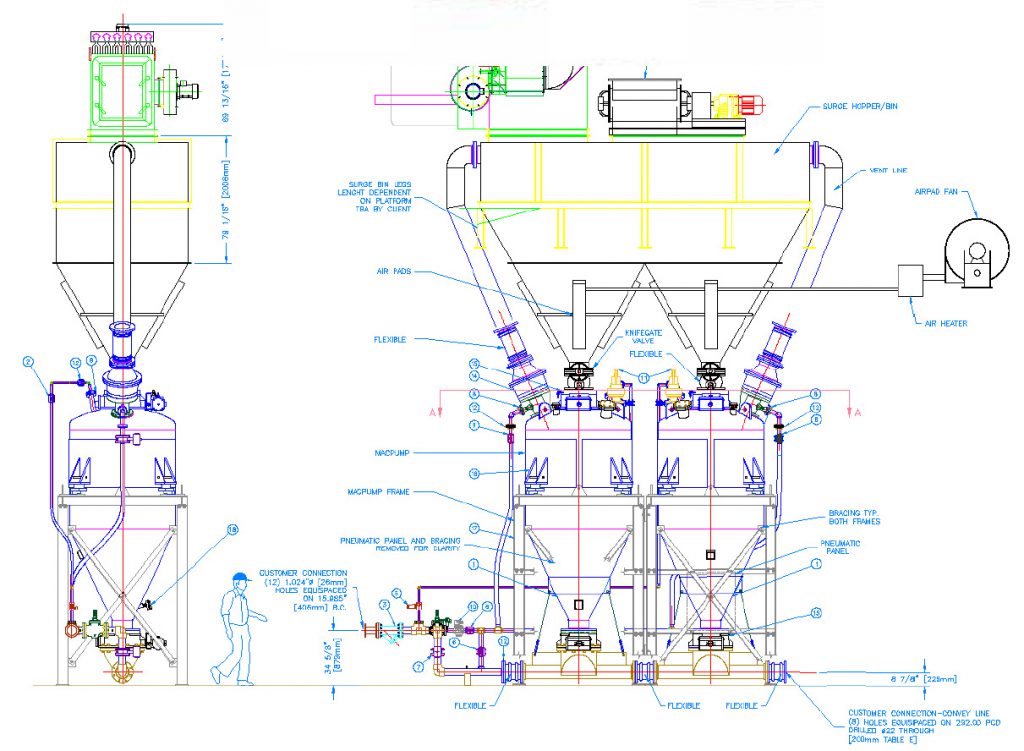

These industrial pumps transfer cement at high rates over long distances. They were a part of a project designed to replace the energy and maintenance of existing heavy screw pumps at a cement plant. The objective was to reduce operating cost of pumping cement and the maintenance that comes along with it.

These industrial pumps transfer cement at high rates over long distances. They were a part of a project designed to replace the energy and maintenance of existing heavy screw pumps at a cement plant. The objective was to reduce operating cost of pumping cement and the maintenance that comes along with it.

The cement plant’s investment in the new systems resulted in a reduction in plant energy consumption and increased reliability. No electrical motors were used – thus decreasing the energy requirements even more.

Primary Objectives

1. Reduce plant energy consumption

2. Ensure plant operating reliability

3. Integrate with plant control systems

Material Characteristics

- Material: Cement

- Bulk Density: 1000 kg/m3

- Size: 360 Blaine

- Temperature: Ambient

- Moisture Content: 0.2%

- Condition: Free Flowing, Dry

Cement Handling Performance

- Transfer Capacity: 125 t/h design rate

- Conveying Distance: 286 m

- Reception Points: 6 Silos

- Air Consumption: 95 Nm3/min

Ask a Question or Get a Price Quote