« Equipment and Systems

-

- Open Mouth Baggers

- Valve Bag Filling Machines

- Bulk Bag Filling Machines

- Bulk Bag Unloaders

- Bag Sewing Machines

- Bag Sealing Equipment

- Bag Handling Conveyors

- Manual Palletizing Systems

- Robotic Bag Palletizers

- Gantry Palletizer Systems

- Automated Pallet Wrappers

- Automatic Bagging

Machines & Systems - IBC Blending

- Stainless Steel Intermediate Bulk Containers

Vibratory Screening and Dewatering

High-capacity wet and dry screening using panels that are constructed from a special high temperature polyurethane material

Vibratory screening equipment is used to screen or classify wet or dry materials, like wet ash or dry frac sand, into multiple grades by particle size. They are also used to dewater or dry waste material before disposal. This type of high frequency vibrating equipment only drives the rectangular polyurethane screen panel, while the frame remains fixed. High capacity screening equipment can screen or classify material ranging in sizes from 1/8 inch (3mm) down to 325 mesh.

Click a link to jump to a section below:

Frac Sand Screening Equipment

Derrick® Stack Sizer®

The Derrick Stack Sizer is a high capacity, multiple deck, wet screening machine capable of high capacity wet screening in a small footprint. A single slurry input is equally divided in a Derrick flow divider prior to the Stack Sizer. Each screening deck then makes a particle size separation on the Derrick Polyweb Urethane screen surfaces. The undersized fraction is collected from all decks in a common manifold to a single discharge. The oversize fraction is collected in the large hopper and discharged to a common point.

- Process up to 150 tons per hour per Stack Sizer

- Low operating cost

- Low horsepower (5HP total) for each Stack Sizer

- Polyweb® urethane screen surfaces typically last 8-10 months or longer thus reducing employee exposure to silica dust

- Minimal dynamic loading for support structure

- Rubber and urethane lined hoppers and feed boxes for long life

- U100 urethane coating sprayed on vibrating screen frame to protect against abrasive sand

Images

Click on a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

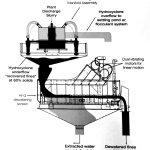

Derrick® Fines Recovery System

Dewater and recover fines from aggregate and sand processing wastewater WITHOUT the use of expensive polymers or chemicals. With many installations throughout North America, the Derrick® Fines Recovery System is proven successful in the field and continues to lead the way for the aggregate industry.

Applications include:

- Drying and cleaning aggregate – dewatering, desliming, degritting and rinsing

- Sand and sand slurry processing and separation – replacement of sand screws

- Solids recovery from dirty water or wastewater

- Reduction of settling pond sedimentation

- Dewatering of solids from dredging operations

- Frac sand processing and recovery free of clays

- Recover up to 80% of the silts and ultra-fine sands that are currently flowing to your settling ponds

- Drastically reduce pond cleaning and maintenance costs and extend the life of settling pond facility

- Reduce settling pond size

- Enhance water quality back to aggregate and sand processing or for public discharge

- Satisfy safety and environmental issues associated with pond use

- Turn wasted material into a marketable product

- Requires NO expensive polymers or chemicals

Images

Click on a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

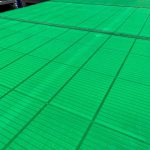

Urethane Screen Panels

Derrick MP screen panels are constructed from a special high temperature polyurethane material. They are a direct replacement for the traditional wire mesh panels currently used in the Rotex MegaTex screeners. These panels have a tapered opening to greatly reduce blinding issues commonly experienced with wire mesh panels. Because of the reduced blinding, the screen production rate can be increased over wire mesh panels. Typical life span is greater than 6 months. Urethane screen panel sizes are available for typical frac sand production.

Images

Click on a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Featured Case Studies

Wet Screening & Dewatering Equipment

High capacity wet screening and dewatering equipment provides a wide range of sizing and classification tasks. Wet screening equipment efficiently screens out fines and classifies oversize particles. Dewatering units have proven throughput of up to 300 TPH (tons per hour) and are designed to maximize solids recovery and minimize wastewater.

Derrick® Stack Sizer®

The Derrick Stack Sizer is a high capacity, multiple deck, wet screening machine capable of high capacity wet screening in a small footprint. A single slurry input is equally divided in a Derrick flow divider prior to the Stack Sizer. Each screening deck then makes a particle size separation on the Derrick Poly Web Urethane screen surfaces. The undersized fraction is collected from all decks in a common manifold to a single discharge. The oversize fraction is collected in the large hopper and discharged to a common point.

- Process up to 150 tons per hour per Stack Sizer

- Low operating cost

- Low horsepower (5HP total) for each Stack Sizer

- Polyweb® urethane screen surfaces typically last 8-10 months or longer thus reducing employee exposure to silica dust

- Minimal dynamic loading for support structure

- Rubber and urethane lined hoppers and feed boxes for long life

- U100 urethane coating sprayed on vibrating screen frame to protect against abrasive sand

Images

Click on a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

SUPERSTACK®

The Derrick SuperStack® provides high capacity, high efficiency separation of fine wet particles. The eight screening decks operate in parallel and include a front-to-back tensioning system that increase the screening capacity up to 3 times that of the best fine screens currently available.

- Compact, stackable design offers abundant access space between decks

- Replaceable stringer and stringer protector units

- Patented Front-to-Back tensioning system ensures ease of operation and rapid screen changes

- Dual oversize launders, assisted by optional push water and / or conveyance-enhancing vibrators, efficiently transport oversize particles

Images

Click on a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

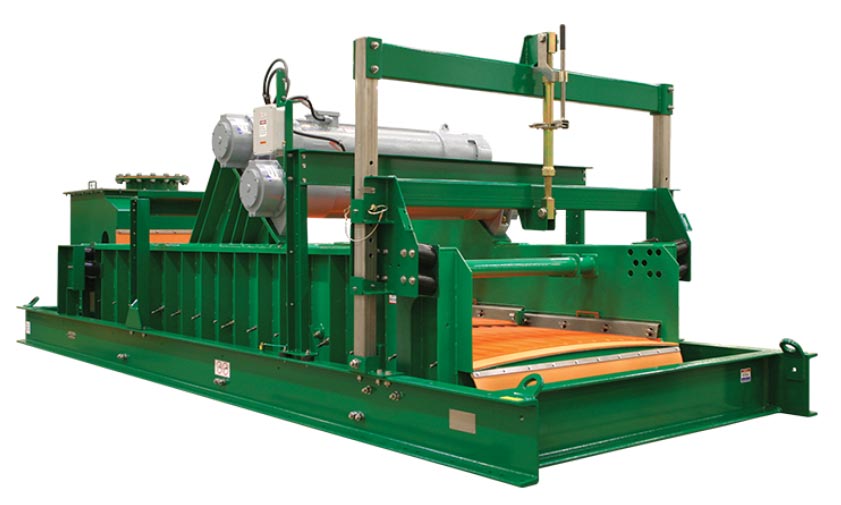

HI-G® Dewatering Machine

The Derrick HI-G® Dewatering Machine is designed to maximize fines separation and recovery and provide drying capabilities to a wet screening and dewatering system. Powered by twin electromechanical 2.5 horsepower Super G® vibratory motors, this unit’s rotary speed (1750 RPM) and stroke length (019 in.) combine to create 7.3 G’s of screen surface acceleration. Water and fine solid separation are conducted efficiently, with component parts designed for maintenance-free operation.

- 4 inch uni-body hydro cyclones arranged in radial design.

- Deck angle can be hydraulically adjusted.

- Fitted with manufacturer's ultra-durable urethane screen surfaces.

- Designed to minimize noise levels (operational level is approx. 81 dBA).

- Efficiently removes silt-sized particles (in range of 12-74 microns) from slurry feed.

- Apex options include modifiable tri-nut and fixed snap-on format.

- Screen panel tension can be easily modified by adjusting Rapid-Change draw bolts.

Images

Click on a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

HI-Cap™ Shaker

This high-capacity wet screening and dewatering equipment is designed to dewater up to 300 TPH (Tons Per Hour) of primary sand products, delivering high-quality production sands (asphalt, concrete, mason, and others). Each unit houses over 62 square feet of screen surface area, of which nearly half is open area, resulting in an efficient and high-volume dewatering capacity.

- Only 10 horsepower required for operation.

- Can be fitted with manufacturer’s ultra-durable urethane screen surfaces.

- A variety of feeding options include large cyclone underflow, screw classifier unit, or a tank classifier cell feed.

Images

Click on a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Linear Motion Screens

Linear motion screens are designed for solids recovery, dewatering, and dilute slurries with low quantities of oversize. These screens are a versatile addition to a variety of wet screening and dewatering processes and are ideal for compact working spaces, with its low headroom requirements and high screening capacity. They efficiently purify viscous slurries, removing grit and other small-particle contaminants.

The screen frame can be angled from +10° to -15°, with highest fluid capacity when locked into an uphill position. The equipment's linear motion conveys oversize materials out of the pool efficiently, discharging them into a dewatering process area.

- Screen openings can be set to a variety of widths, from 10mm to 38 microns.

- Very little headroom required to operate.

- Urethane screens feature wide-open area, also available with woven wire screens.

Images

Click on a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Repulp Screen

The Repulp Screen efficiently screens out fines and undersize particles, resulting in clean and consistent oversize material. Spray nozzles are focused upon rubber-lined wash troughs (instead of being focused directly on screen surface), reducing wear and providing evenly distributed fluidization. Vibrating motors feature sealed bearings that are permanently lubricated and require minimal maintenance.

These machines feature multiple stages of screening and repulping, resulting in the highest rate of undersize particle removal possible. Repulp screens can be equipped with a split undersize hopper, allowing for a variety of separation sizes, and cut points.

- Available in widths from 18 - 56 inches.

- Available in lengths from 60 - 168 inches.

- Urethane screens feature wide open area, also available with woven wire screens.

Images

Click on a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

High Shear Screen

The High Shear Screen effectively processes clay slurries. While traditional wet screening and dewatering machines feature a low plane of incline (resulting in bridging and blockage issues with platy minerals found in clay), High Shear Screens are set to a 45 degree panel angle. The result is a screening solution that can handle difficult slurries and platy minerals.

- High capacity at 270-400 mesh cut points.

- Removal of over 99% of grit particles (+325).

- Optional installation of spray misting nozzles.

- Multiple feed point configurations are available (single and double).

Images

Click on a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Multifeed

The Multifeed wet sizing screen is made up of three independent screening machines that provide three times the effective width of a conventional screen, mounted in a single frame and driven by one vibrating motor. The three separate feed streams are divided equally through a flow divider system located on the machine.

- Flow dividers split incoming feed slurries to individual screen feed points

- Screen wear is minimized using low, uniform feed presentation

- Special collection manifold with launders under the end of each screen collects oversize product for discharge to a common chute. Undersize particles bypass the manifold for collection in a common discharge hopper.

- Wet sizing capabilities for 3/8 inch down to 400 mesh.

Images

Click on a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Featured Case Studies

Dry Screening Equipment

The dry screening equipment featured below use high speed, low amplitude, and vertical elliptical motion to screen dry materials such as sand, iron powder, nickel powder, polyethylene pellets, coal, glass, and many other materials. These machines produce low amounts of sound and are fully enclosed for dust suppression. Light-weight screen panels and hinged and clamped covers provide easy screen inspection, removal, and installation.

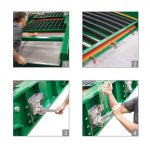

Front-to-Back™ Dry Screening Machine

The Front-to-Back (FTB) dry screening machine provides increased screening capacity, improved efficiency, and extremely fast screen panel changes. Customers using the FTB machine report screening capacity increases up to 50% with improved efficiencies in products ranging in size from 0.25 inch (6.35mm) down to 400 mesh (38 µm).

- Rotating the screen panel tensioning 90 degrees positions the crown of the screen parallel to the material flow assuring an even distribution of material across the entire width of the screen

- Increased capacity

- Reduction in screen panel wear increasing the life of the screen

- Elimination of blinding

- Change a screen panel in 4 simple steps

Images

Click on a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Traditional Dry Screening Machines

These dry screening machines have been in use for over 60 years in the industrial minerals industry. They utilize a true linear motion to achieve higher screening capacities with smaller floor footprints. Screen pellets, powders, sand, crushed glass, coal, and many other types of materials that require fine screening.

- Low sound production

- Dust suppression

- Easy access to light-weight screen panels for inspection, removal, and installation

- Multiple machine sizes and configurations available including up to 4 decks

Images

Click on a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

« Back to Equipment and Systems