This automated IBC discharge system empties battery powder from one intermediate bulk container into an empty IBC under a nitrogen purge. This type of powder handling system is used during the battery manufacturing process.

NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

View bulk processing equipment installations used for mixing, packaging, screening, and automation for a wide range of applications. We can provide custom designed systems, as well as a single machine or spare part.

View examples of general application bulk processing equipment below. For more specific case studies and projects, please see the linked category menu or view our product lines.

Ask a question or Get a Price Quote. Use our Express Contact Form or call: (979) 217-1480

Category | Bulk Processing Equipment | Intermediate Bulk Containers or IBCs |

This automated IBC discharge system empties battery powder from one intermediate bulk container into an empty IBC under a nitrogen purge. This type of powder handling system is used during the battery manufacturing process.

Category | Automatic Bagging Machines | Bag Handling Conveyors | Bulk Processing Equipment | High Speed Robotic Palletizers |

One of our manufacturers recently designed and implemented an automatic depalletizer and bag dump station for a customer in the chemical industry. The system involves a robot depalletizer that unstacks 50 lb. bags of chemical powders from a shipping pallet located to the left and right side of the robot. The bags are picked up 3 at a time and placed 1 at a time on a conveyor that transports them to an inclined belt conveyor that discharges them into automatic bag dump station. In this article, we’ll provide an overview of the system, explain how the robot depalletizer system works using a vision system, and outline the features and benefits of the system.

Category | Bulk Bag Fillers | Bulk Bag Unloaders | Bulk Processing Equipment |

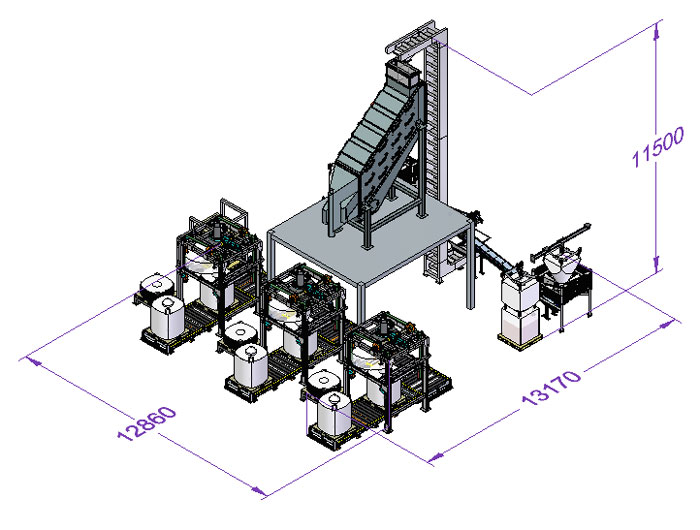

Drawing of a high-speed big bag filling system. Measurements are in millimeters.

In this hi-speed big bag filling system, raw sugar is unloaded from big bags, or bulk tote bags, conveyed to a vibratory screen where it is separated into 3 fractions and one waste fraction, and then re-packaged into big bags.

Category | Automatic Bagging Machines | Bulk Processing Equipment | Open Mouth Bagging Machines |

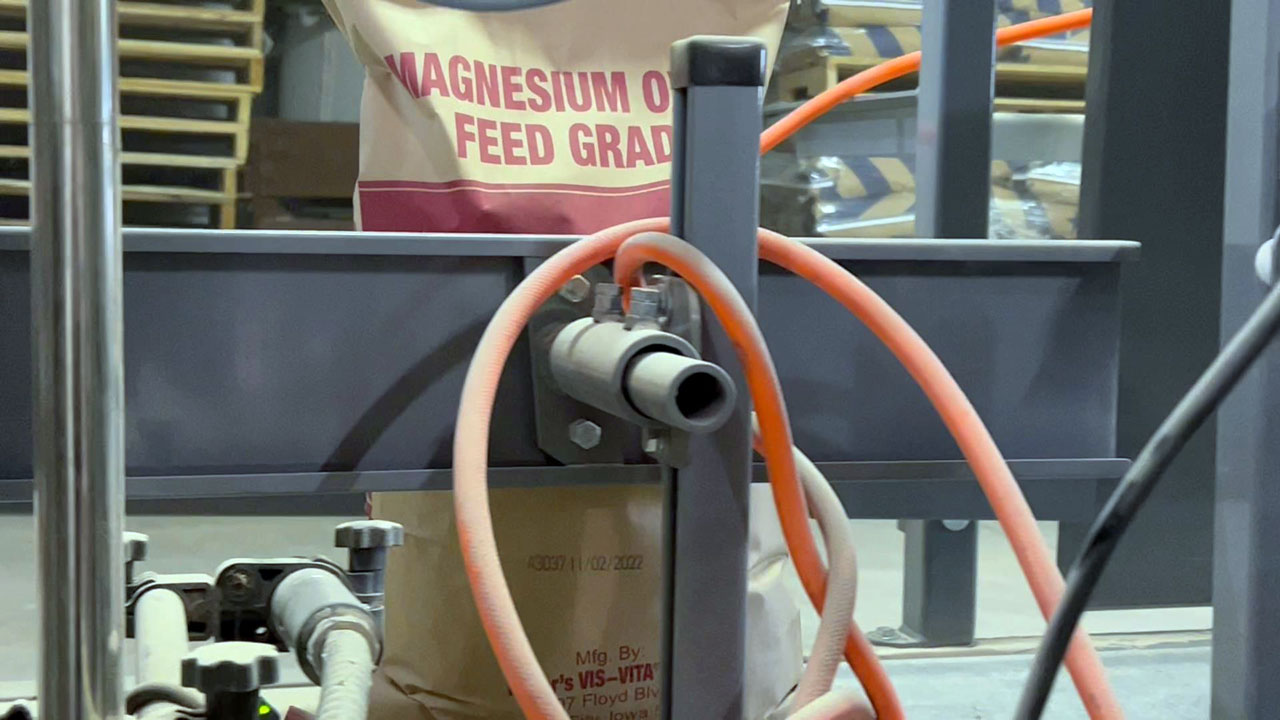

Lot / batch code and date printed on bottom part of bag after passing print head

This inkjet code printer was put to the test in an animal feed and minerals packaging line. Multi-wall open mouth paper bags, filled with animal feed are sewn shut. Then, they pass in front of the code printer on a conveyor before robotic palletizing. As each bag passes the code printer, a lot code and date are printed on the bottom part of the bag. Each of these unique codes helps to identify when the batch of product was produced and packaged.

Category | Bulk Processing Equipment | Intermediate Bulk Containers or IBCs |

An Intermediate Bulk Container (IBC) System is used to prepare a homogeneous dry blend of base polymers and additives before the extrusion phase in a plastic compounding process. Plastic compounding and toll processing companies first use an IBC system to create a lab formulation or test to confirm final product characteristics before creating a masterbatch. Once a final product has been confirmed, the same IBC system is used to create a larger batch or production run.

IBC is easily transported by forklift to other discharge stations

This type of set up using an Intermediate Bulk Container (IBC) System is also known as a decoupled system because ingredients can be moved, mixed, and blended independently inside the IBCs.

Category | Bulk Processing Equipment | Intermediate Bulk Containers or IBCs |

Stainless steel IBC container above powder sachet packing machine

Stainless steel, food grade IBC containers store, transport, and discharge drink mixes and hydration powders into a sachet packing machine.

Category | Automatic Bagging Machines | Bulk Processing Equipment |

Use an automated bagging system to fill boxes and baler bags with small pre-packaged, form fill and seal (FFS) bags or pouches containing products such as grains, sugar, flour, salt, powders, and more. This type of automation can enhance your end of line packaging and provide a more convenient way to ship and handle smaller bags together as a stackable unit.

Use an automated bagging system to fill boxes and baler bags with small pre-packaged, form fill and seal (FFS) bags or pouches containing products such as grains, sugar, flour, salt, powders, and more. This type of automation can enhance your end of line packaging and provide a more convenient way to ship and handle smaller bags together as a stackable unit.

Category | Bulk Processing Equipment |

Curved vibrating conveyors can be used to meter, sort, or align bulk material in a processing system. The material exiting the conveyor will be in a single or double line for the next stage in the process.

In the picture shown below, the conveyor lines up 18 inch by 12 inch, 35 pound metal plates into a single file line to convey under a camera for inspection.

Category | Bulk Processing Equipment |

This type of vibrating conveyor has a large pan and trough. It is used to convey heavy, abrasive, and very hot materials through bulk processing systems.

They are also used to convey bulk solids for a wide array of applications including aggregates, minerals, rebar, sand, coal, ash, ore, castings, molds, pharmaceuticals, and food products. Standard sizing options are available, as well as custom-engineered products tailored to fit specific customer requirements.

Category | Bulk Processing Equipment | Small Vibratory Feeders | Vibration Tables |

This box filling machine fills empty boxes with chopped metal fibers by weight. The metal fibers are added to concrete to increase its strength.

Category | Bulk Processing Equipment | Screening Fine Sand, Powder, and Chemicals |

A US lime producer needed to replace 2 brute force vibratory screens at their limestone quarry due to constant failure of the drive bearings, lost production time, and maintenance costs. After discussions with plant engineering, a single unit with a natural frequency drive screen was selected to process crushed limestone at a rate of 650 tons per hour.

Category | Bulk Processing Equipment | Pneumatic Conveying Systems |

This pneumatic conveying system was installed at a paint production facility and was used to convey titanium dioxide over a distance of 400 feet to material receiving hoppers. It was also designed to pneumatically convey calcined clay, calcium carbonate, mica, amortized silica, and feldspar.

Category | Bulk Processing Equipment | Industrial Vibration Motors |

These industrial vibration motors are used on bulk processing equipment such as large feeders, conveyors, vibrating tables, vibratory screens, bulk bag filling machines, big bag unloaders, and more.

Category | Bulk Processing Equipment |

Baghouse for Asphalt Plant

This baghouse, or dust collector, was installed at an asphalt plant. It increased production capacity by 33%.

The asphalt producer had an undersized system and could not produce at the capacity needed in a reasonable time. Trucks waited up to 2-1/2 hours for each new batch of asphalt. The problem was particularly urgent since the business had grown substantially.